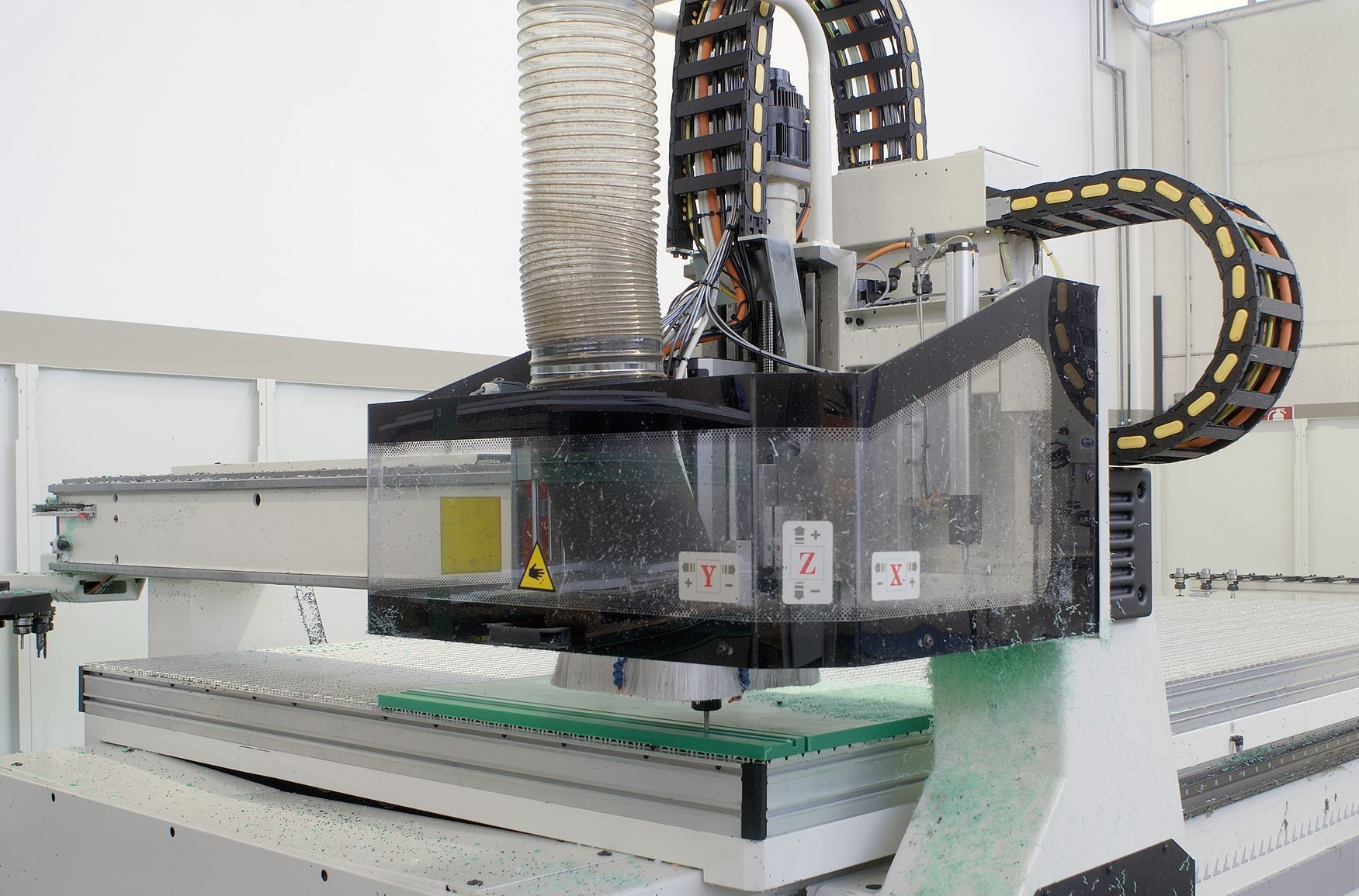

PANTOGRAPH DEPARTMENT

TECHNOLOGIES FOR EXCELLENT RESULTS

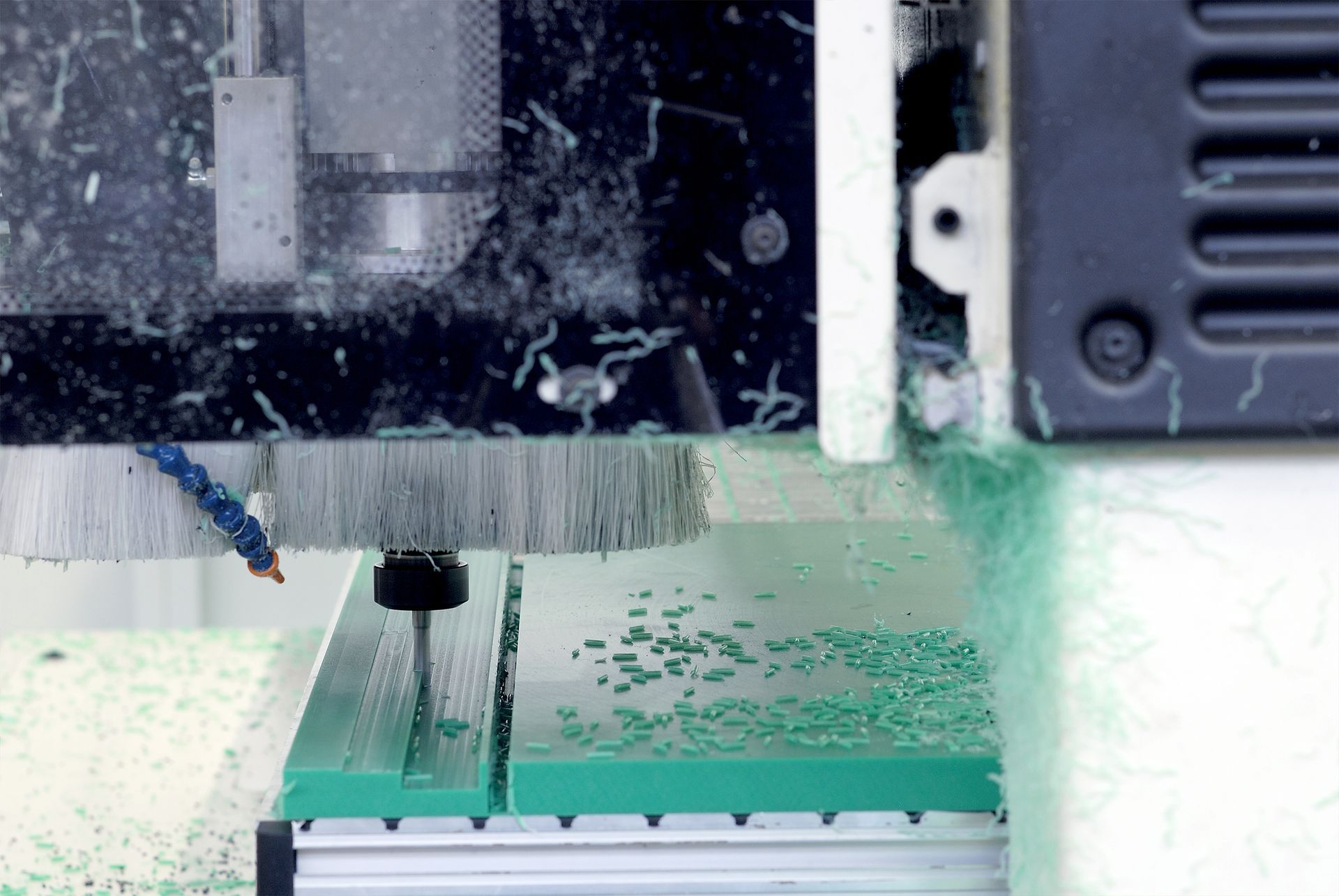

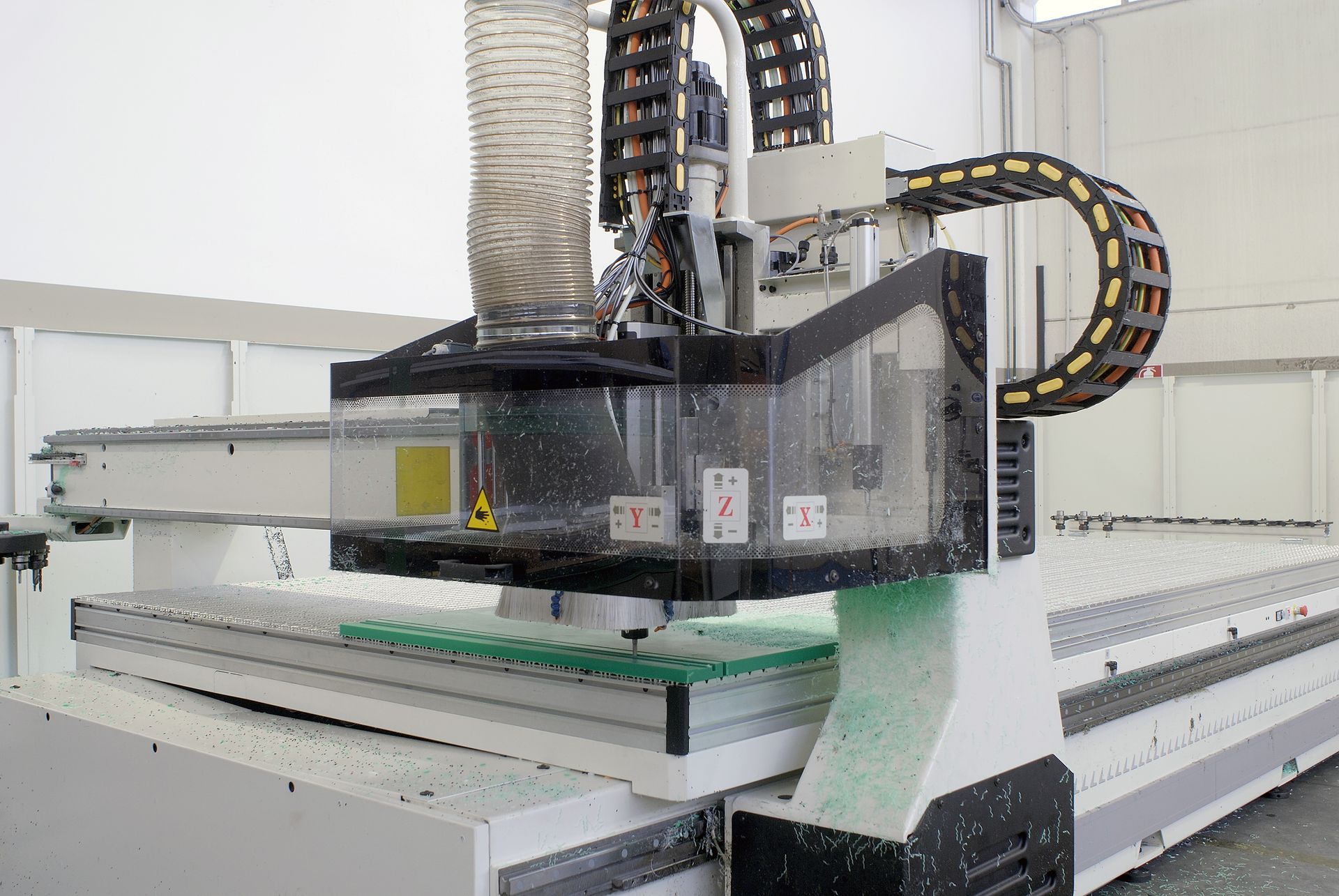

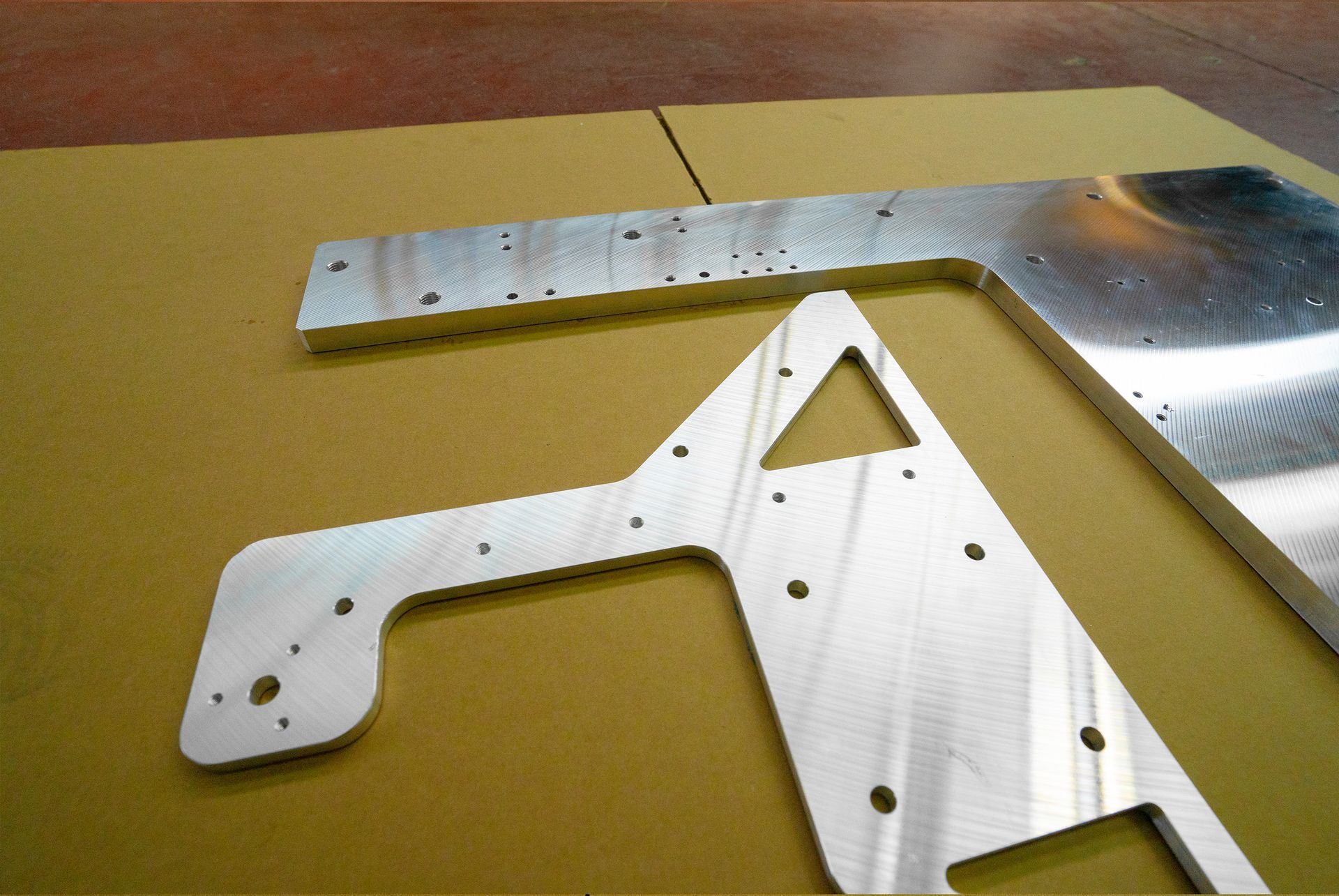

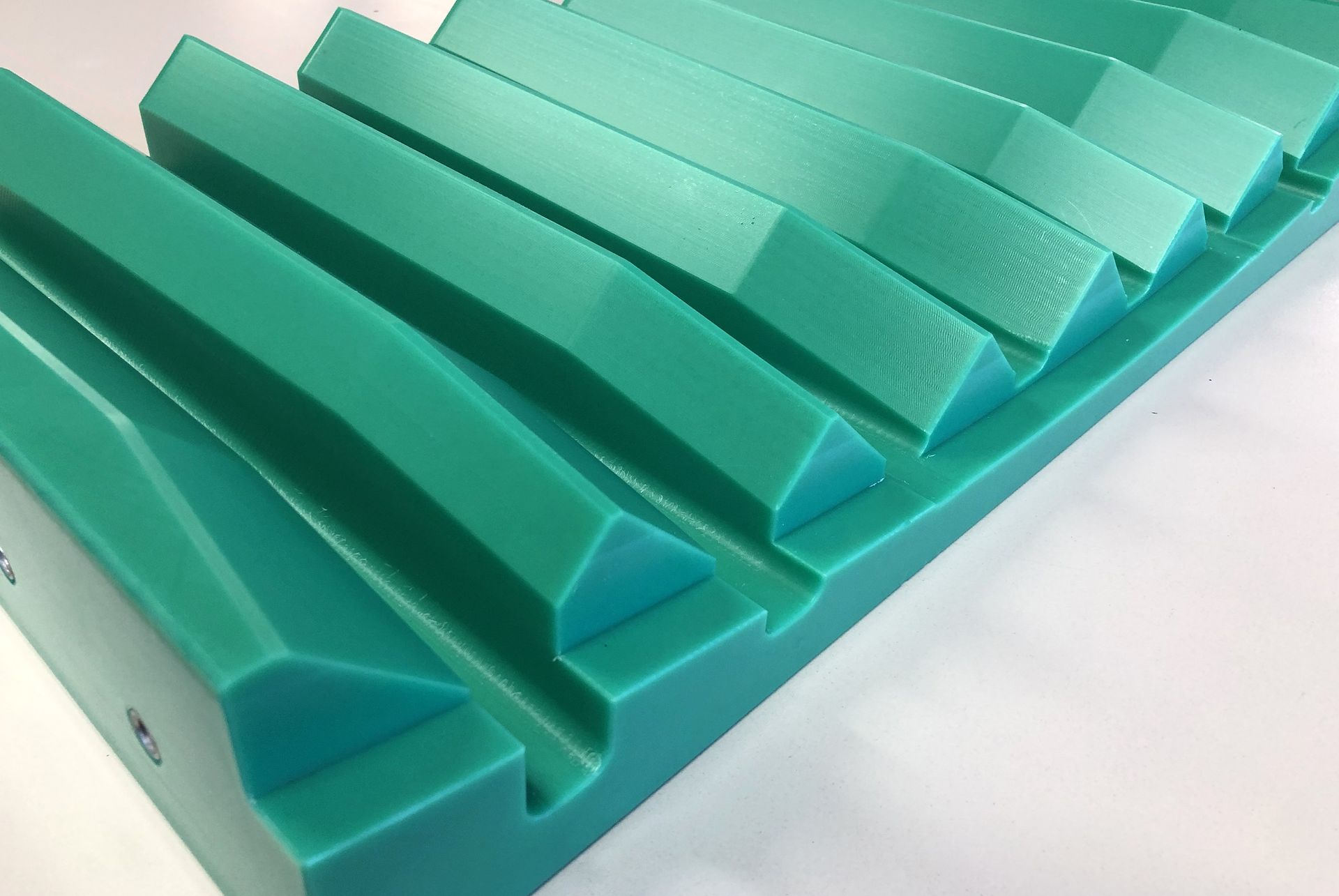

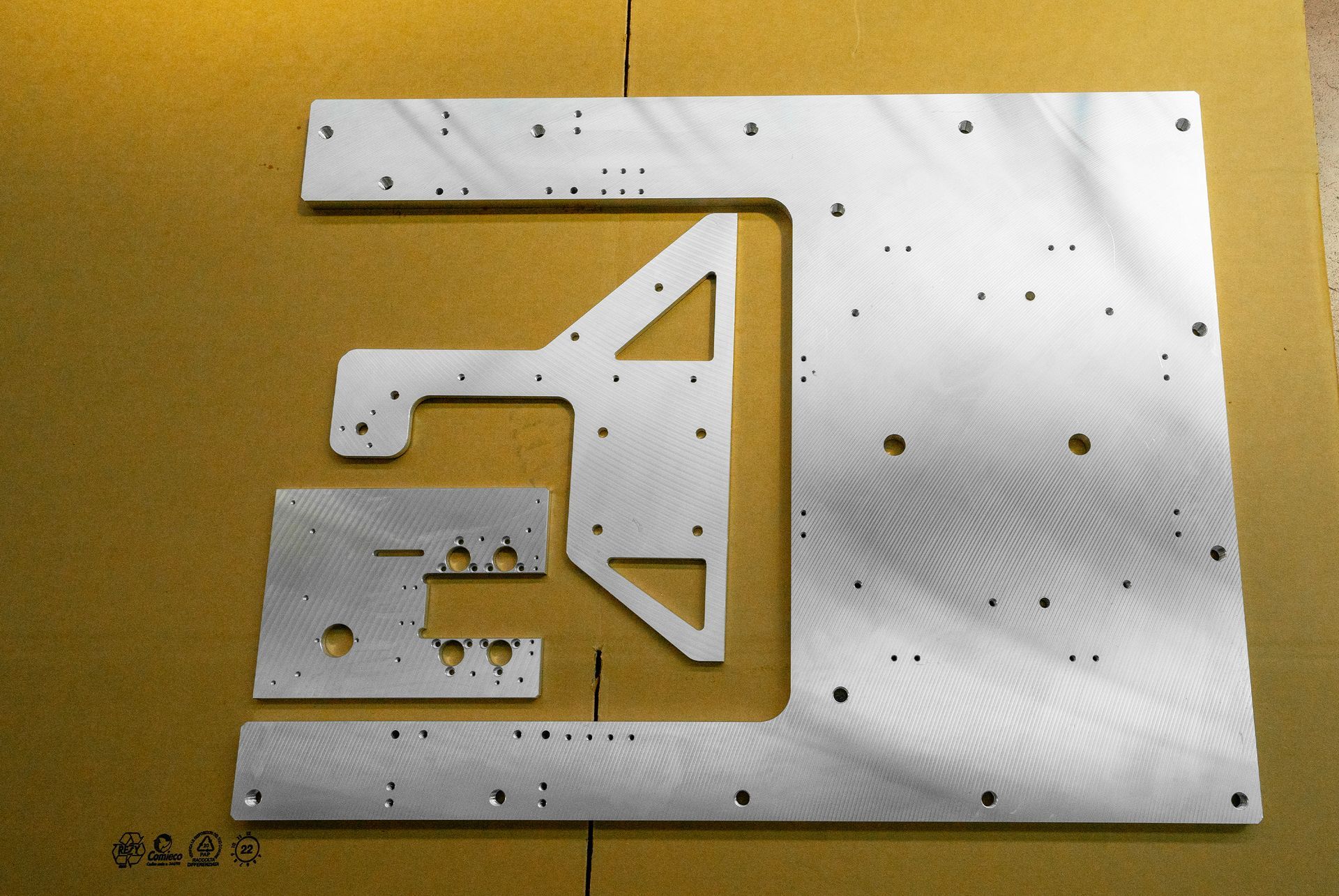

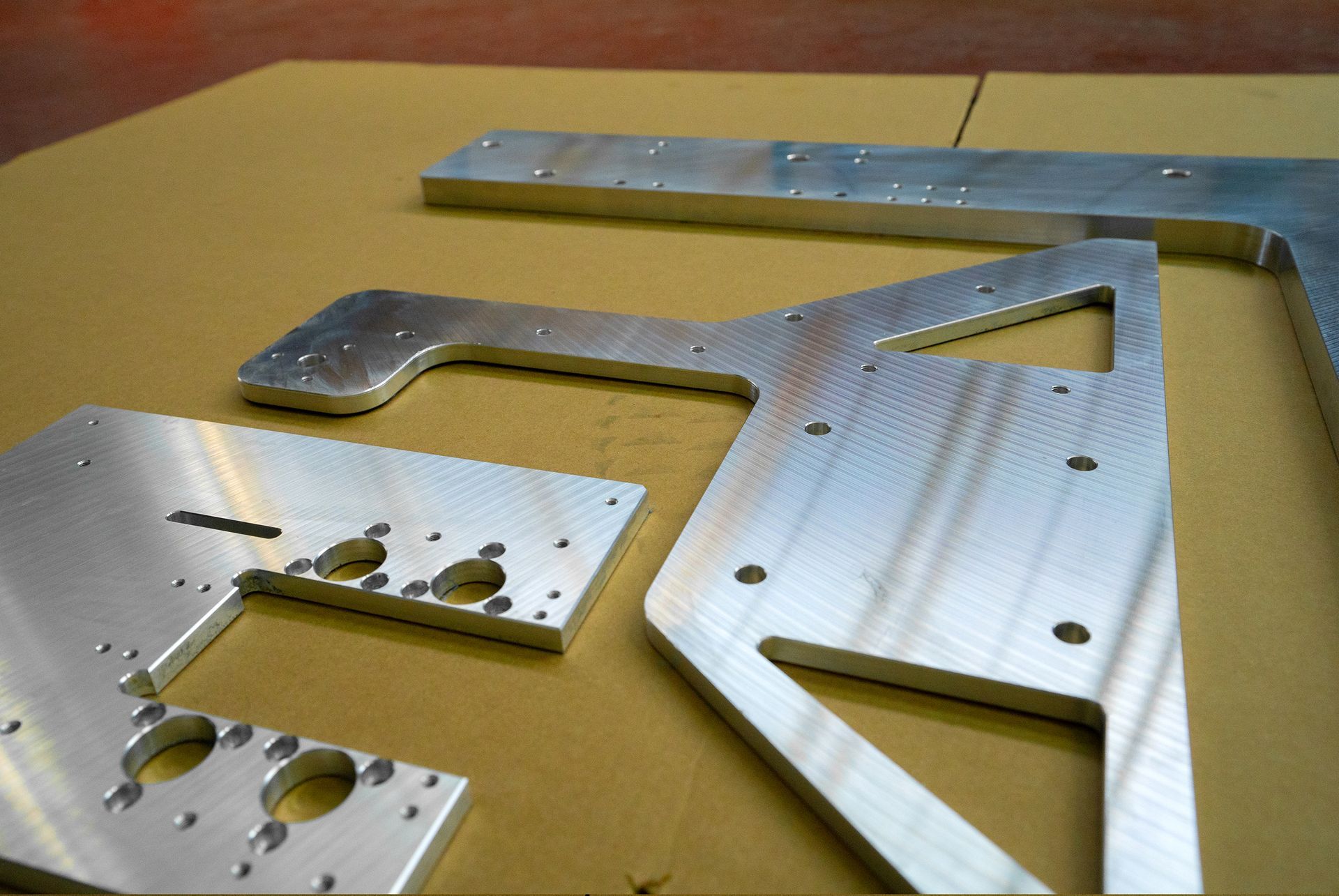

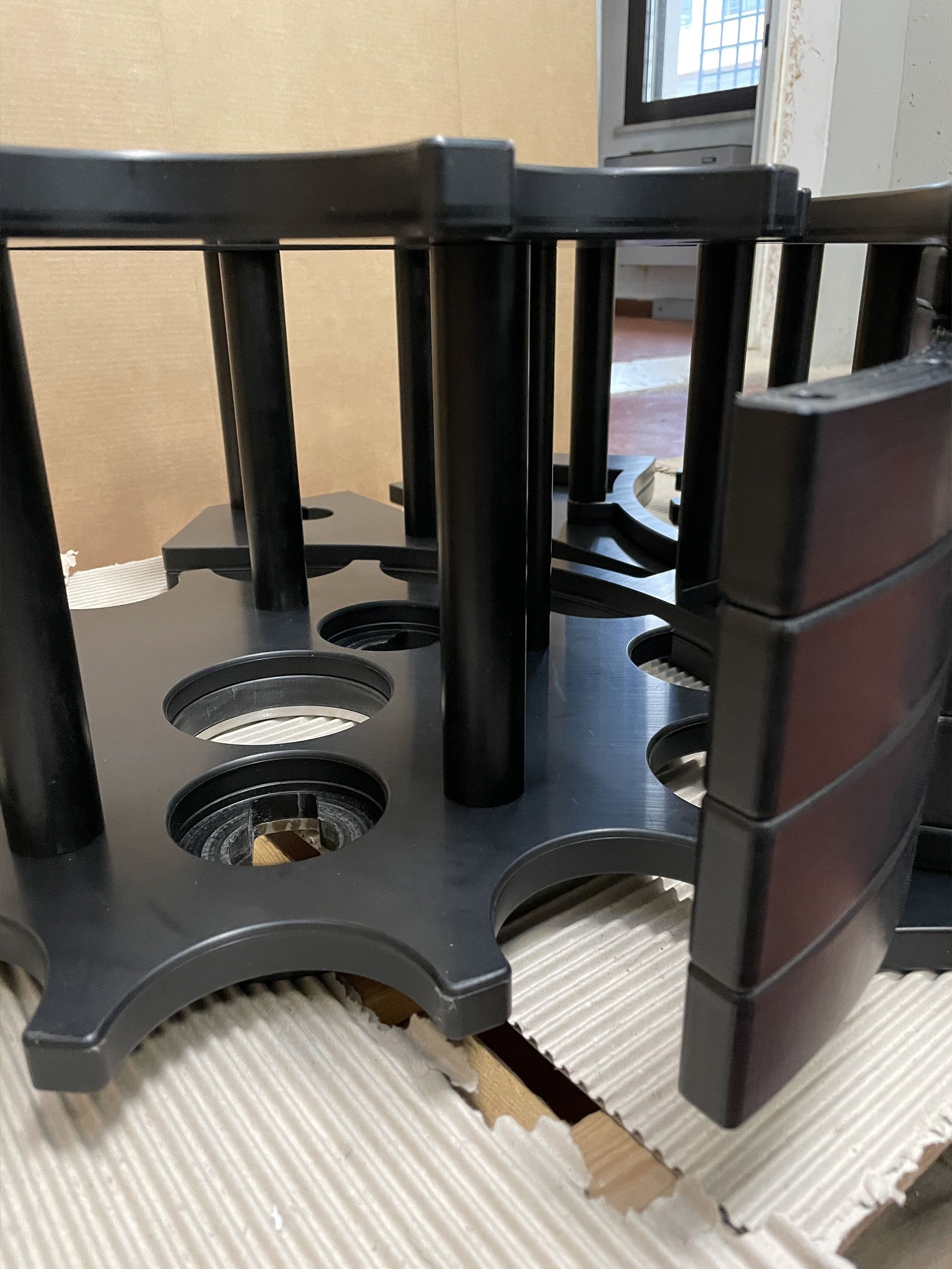

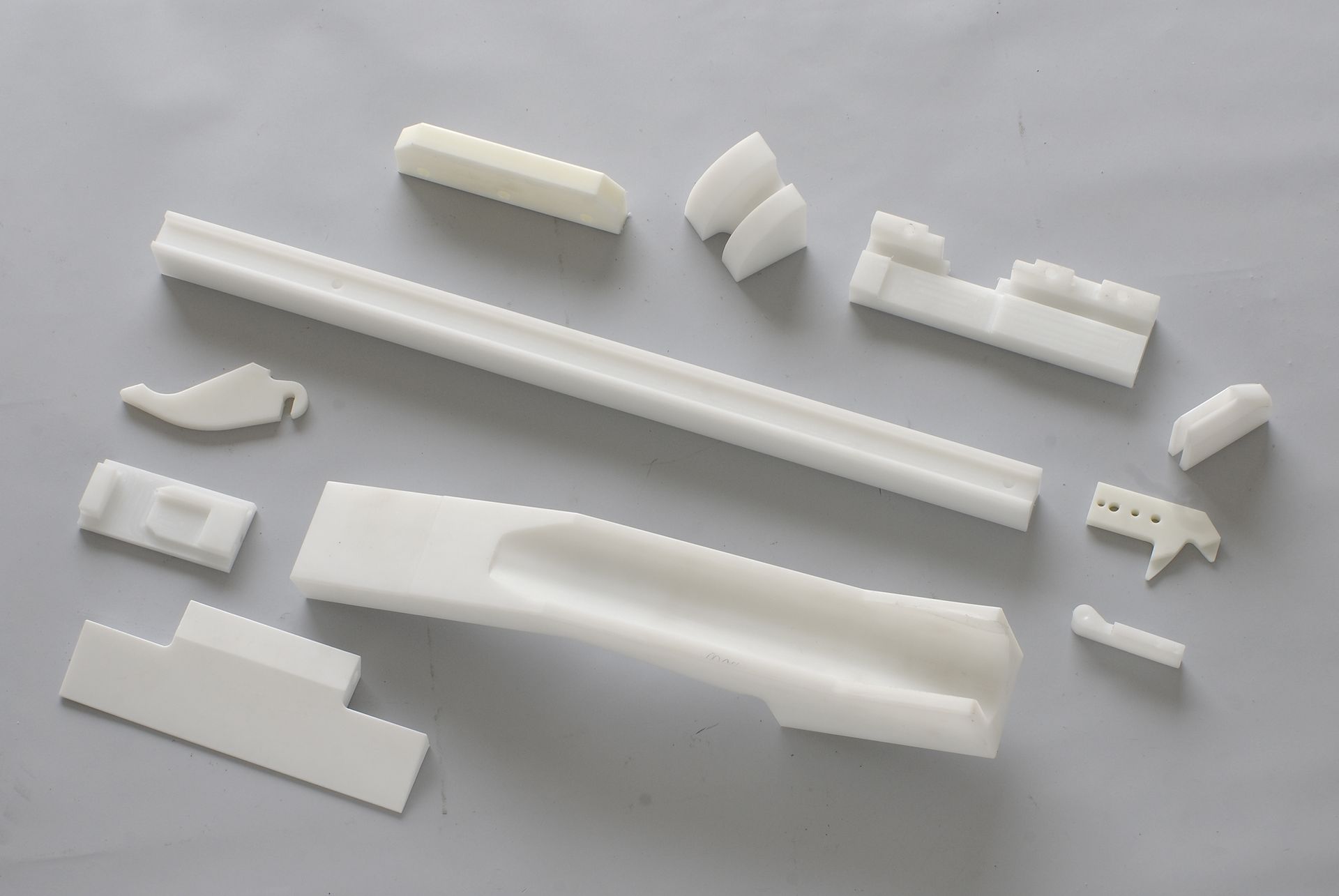

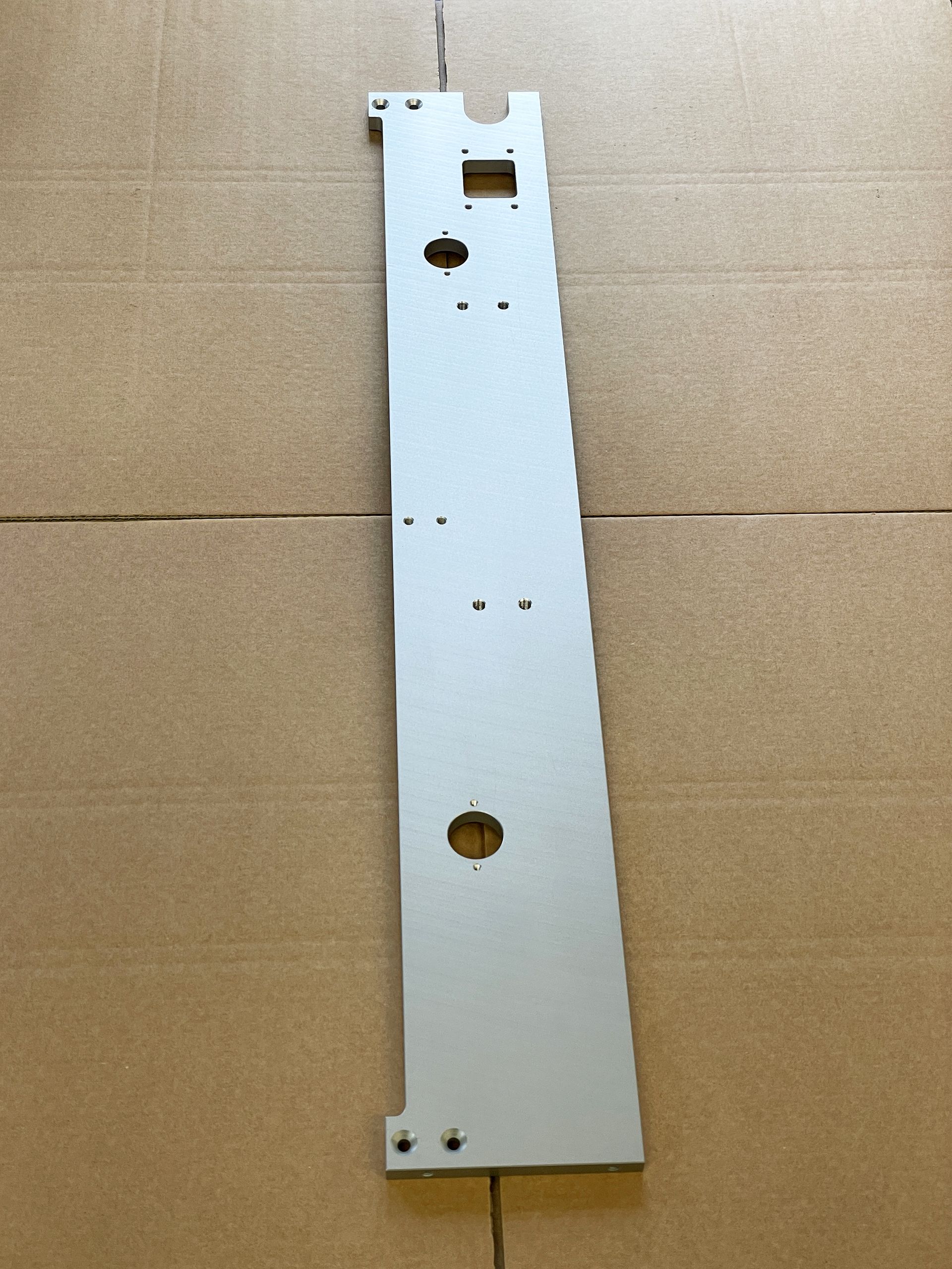

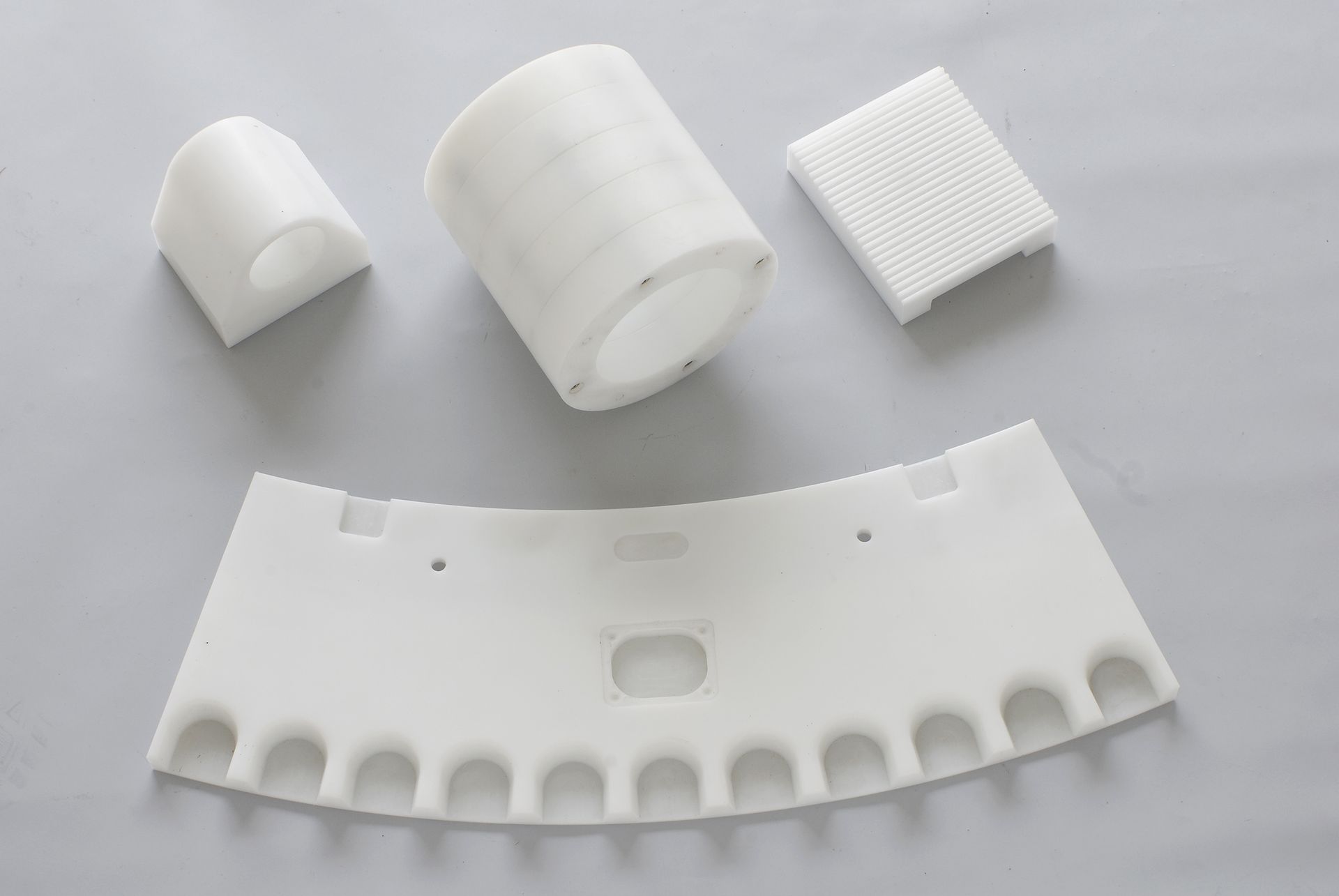

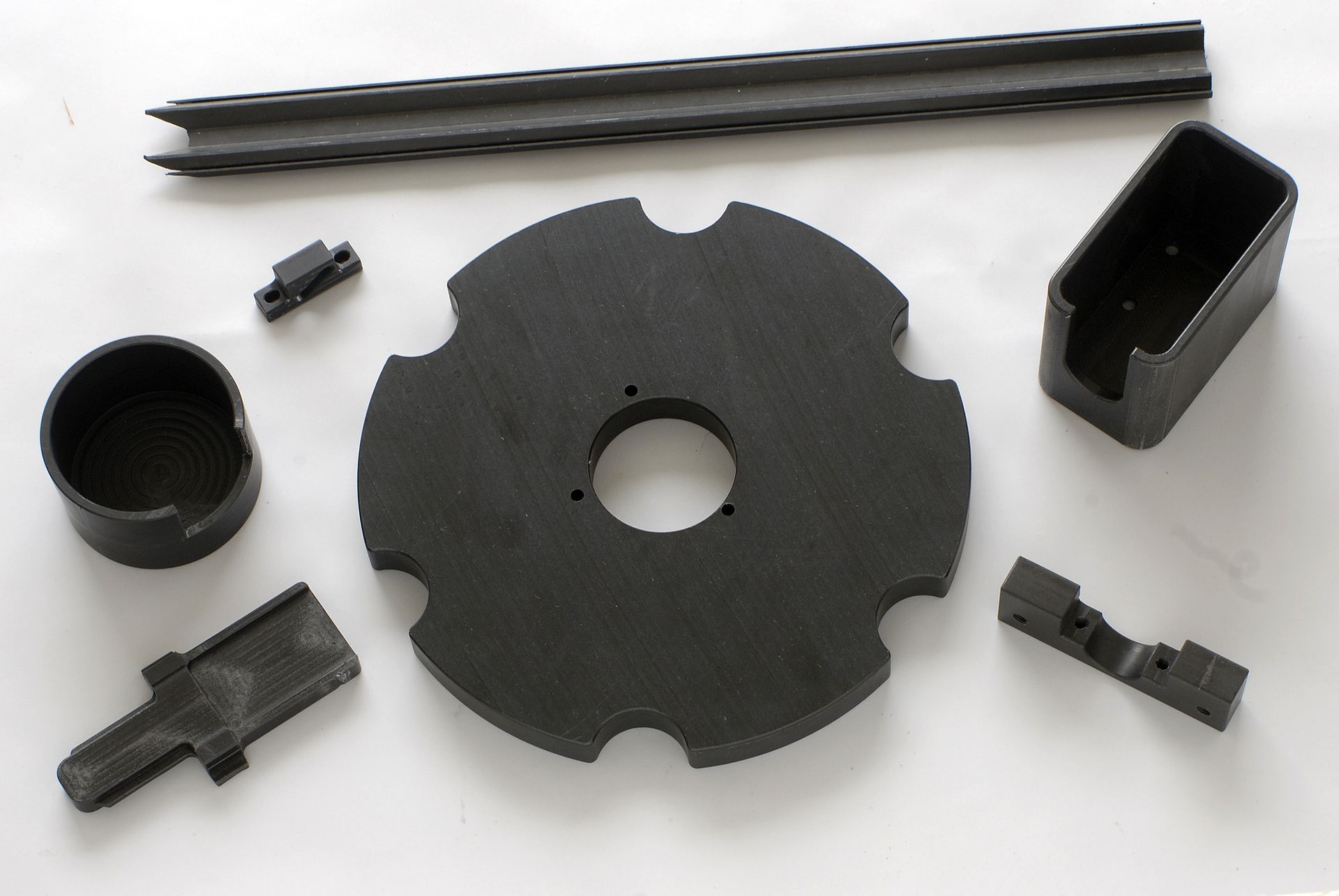

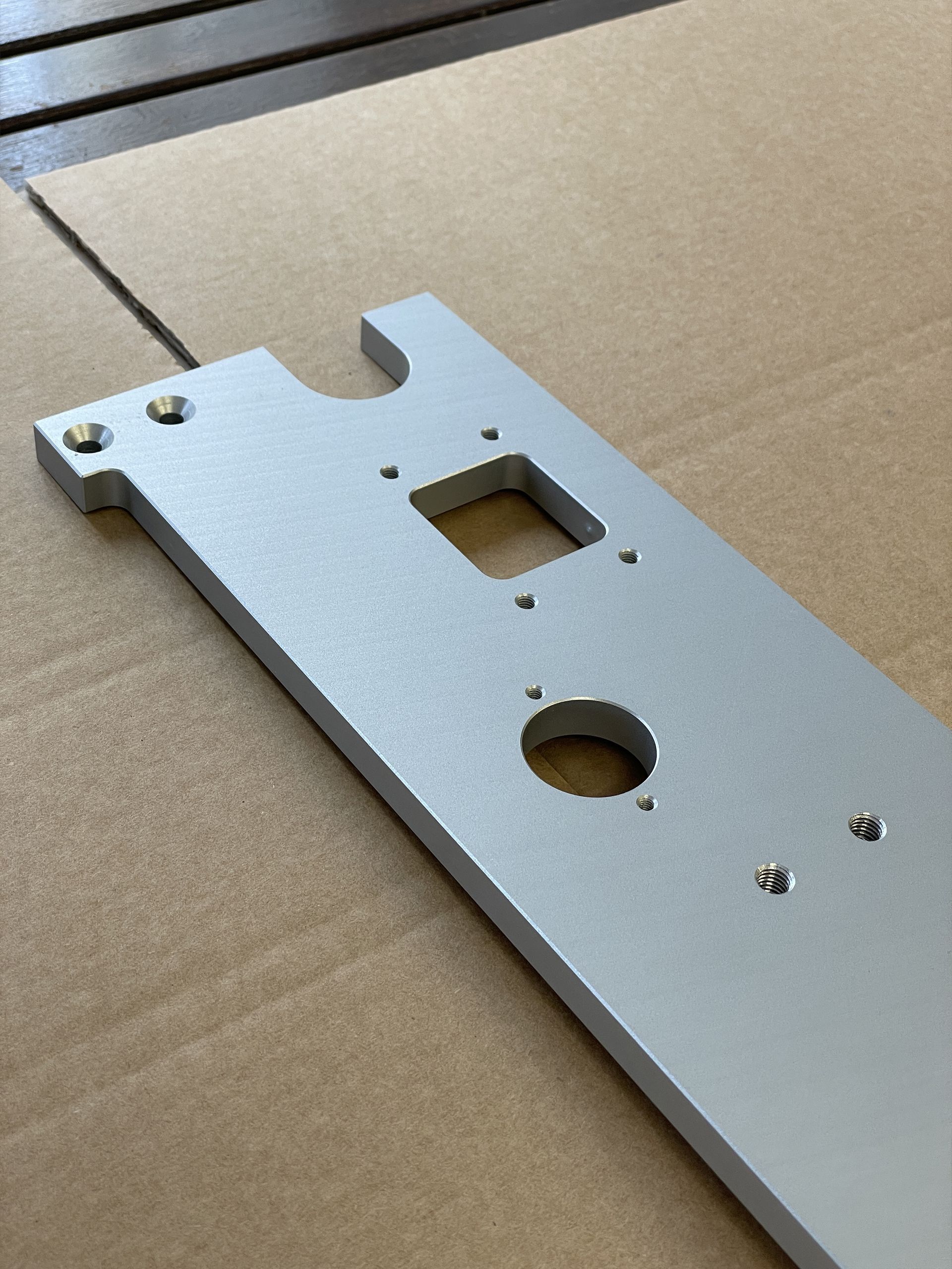

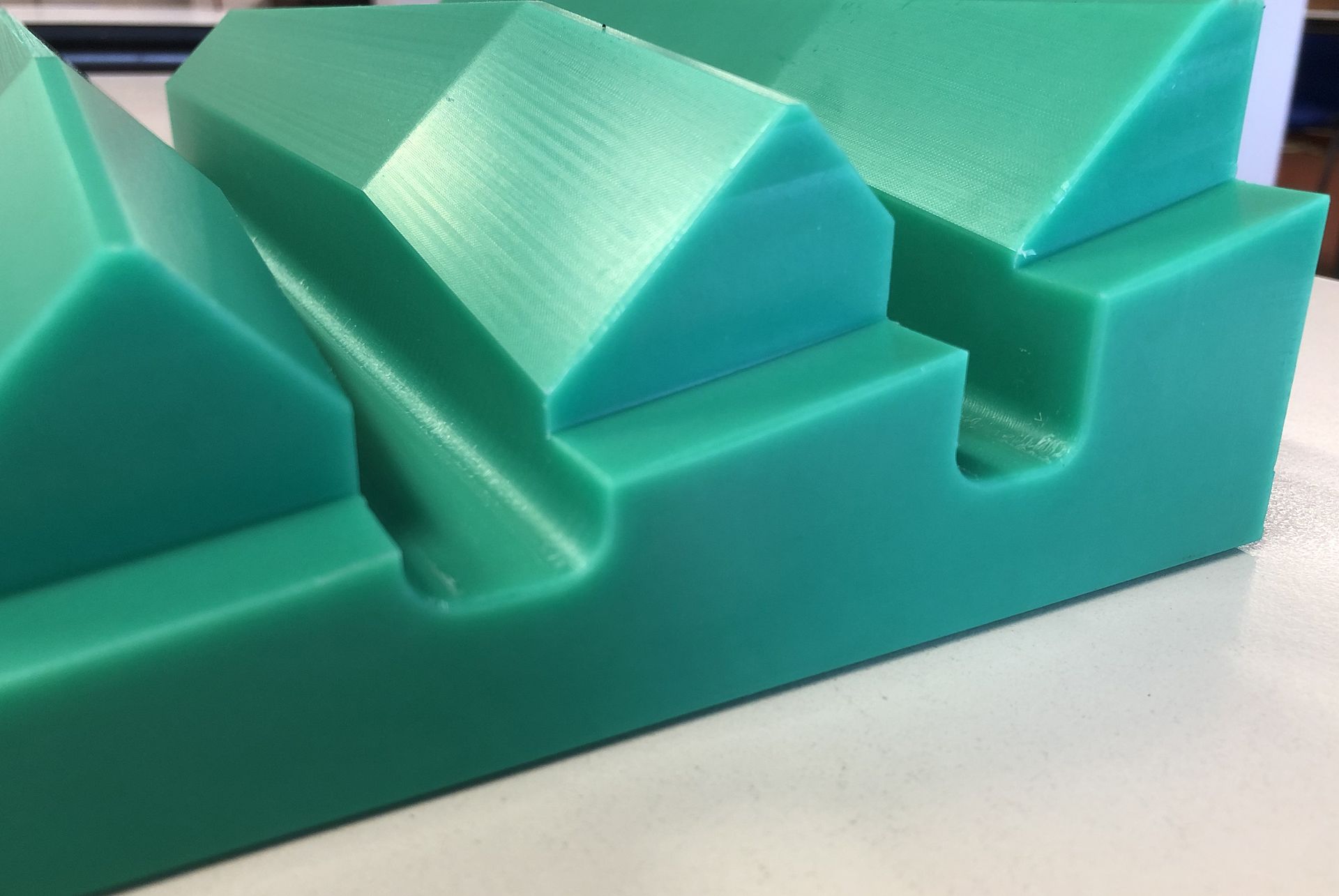

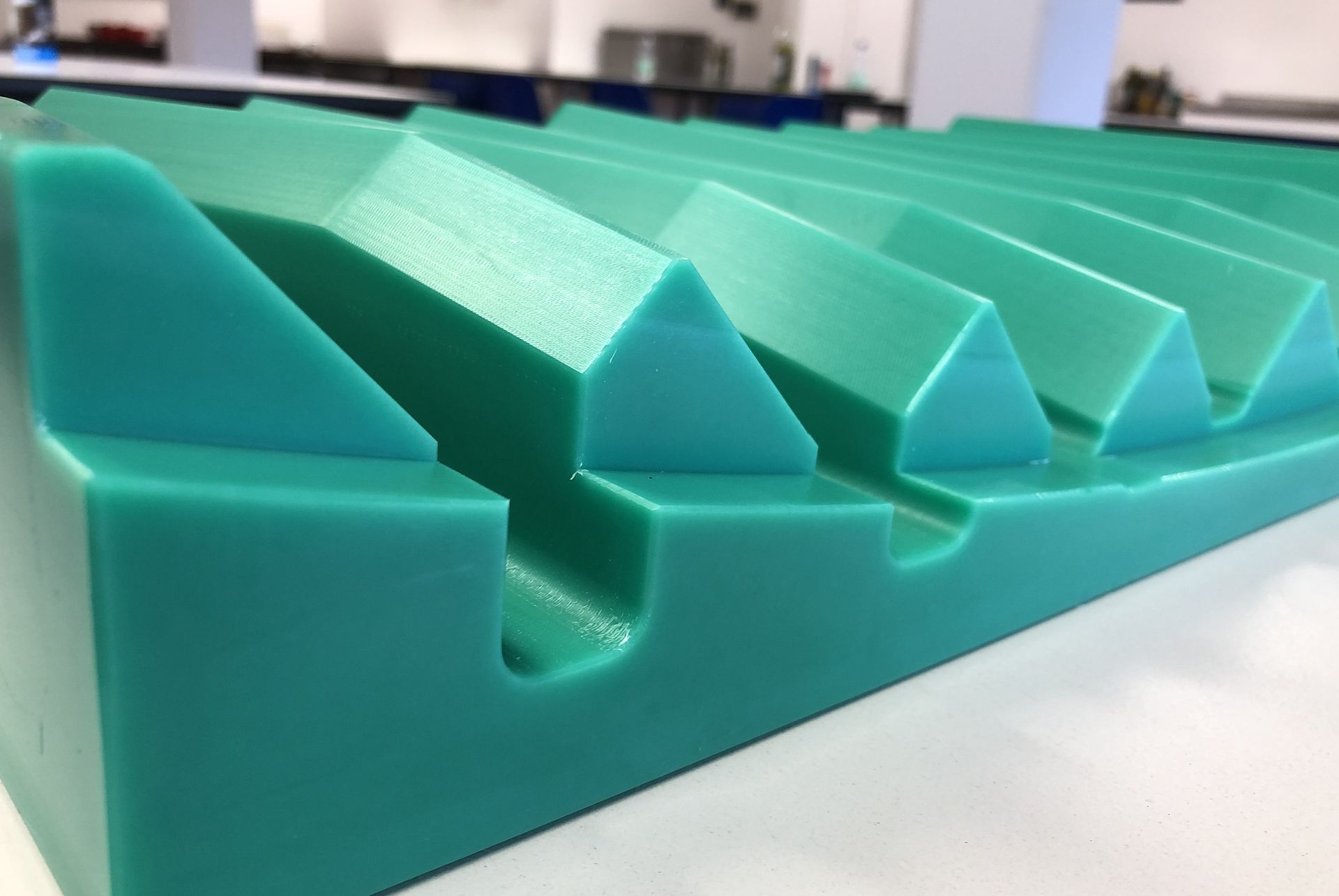

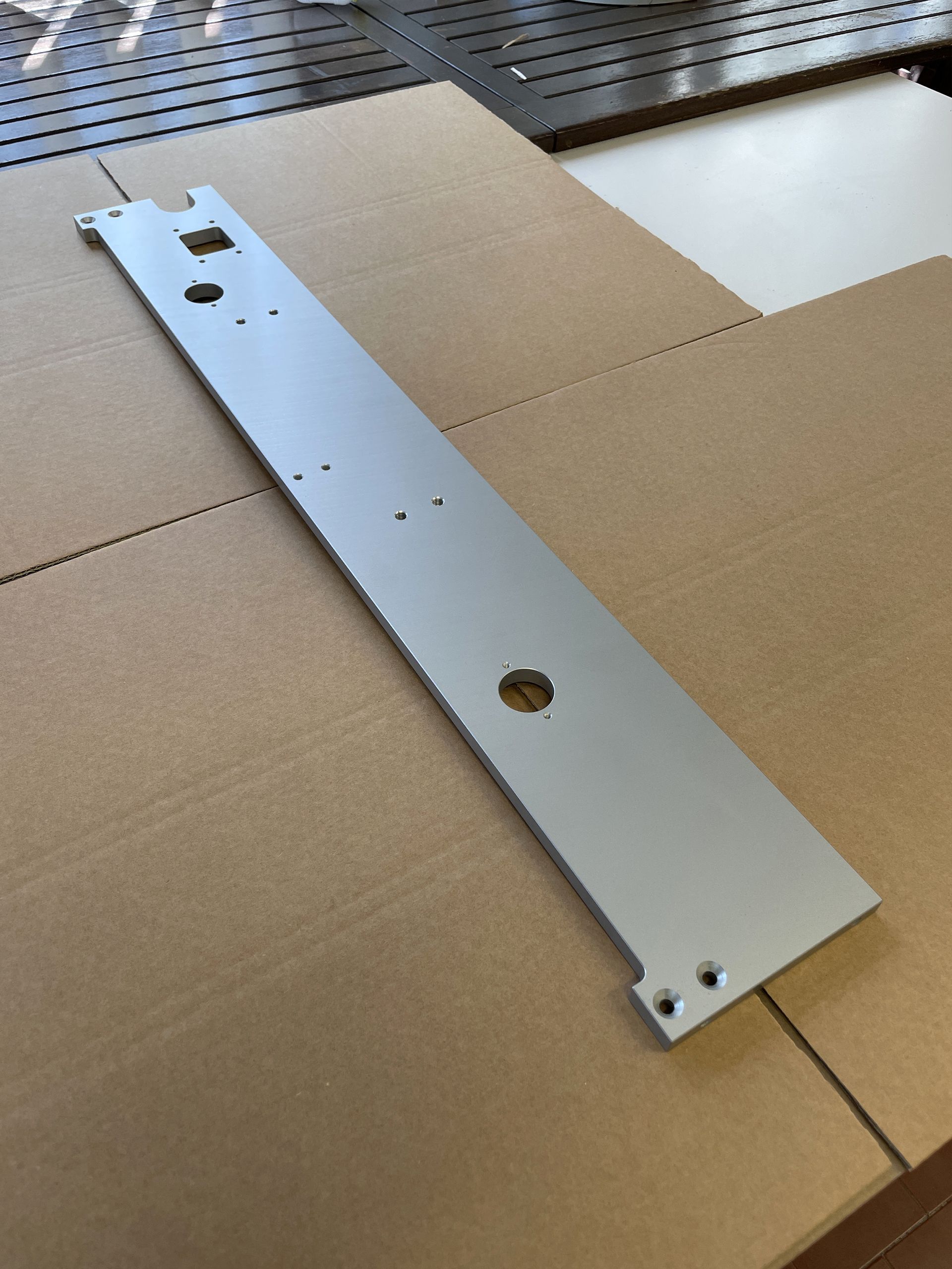

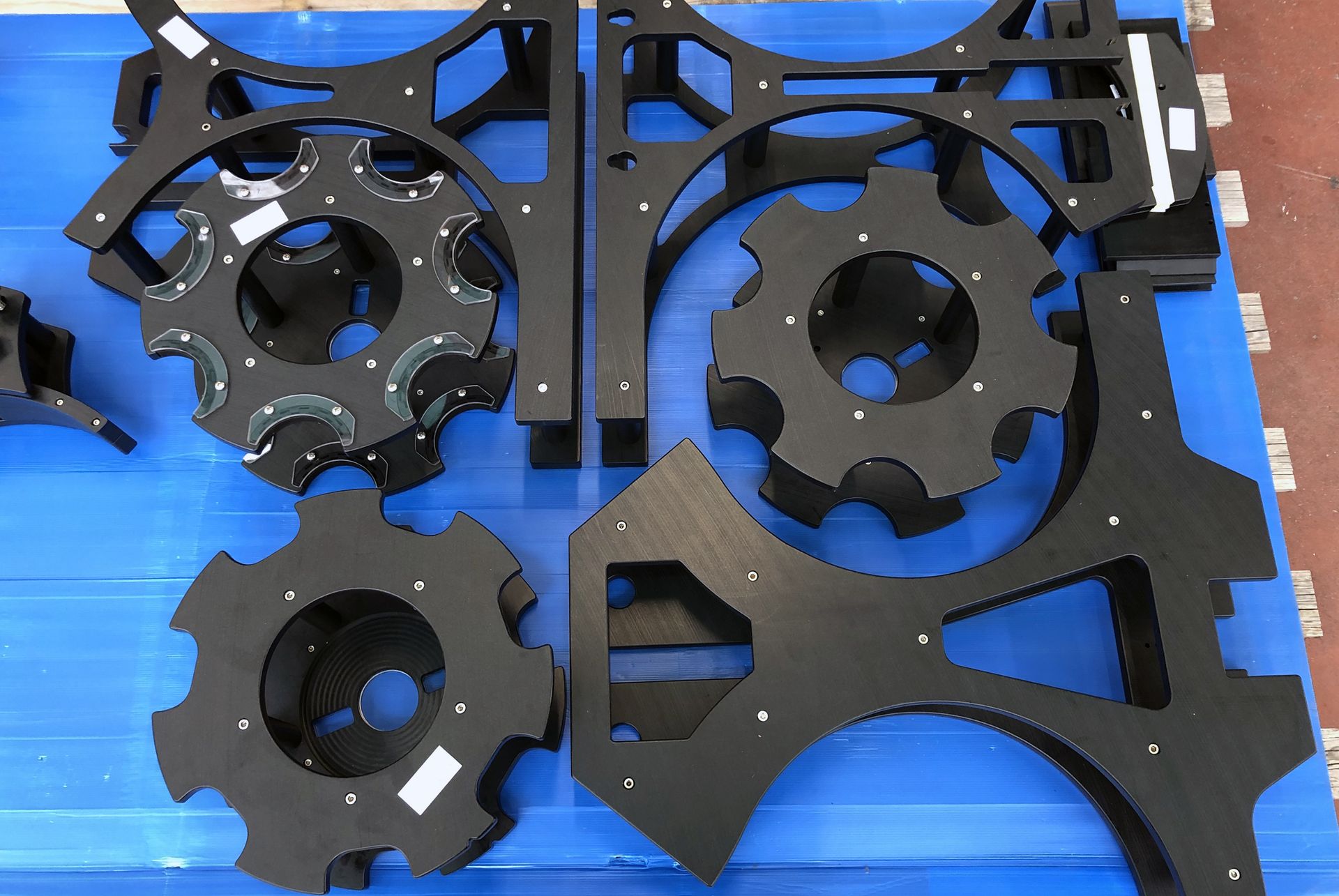

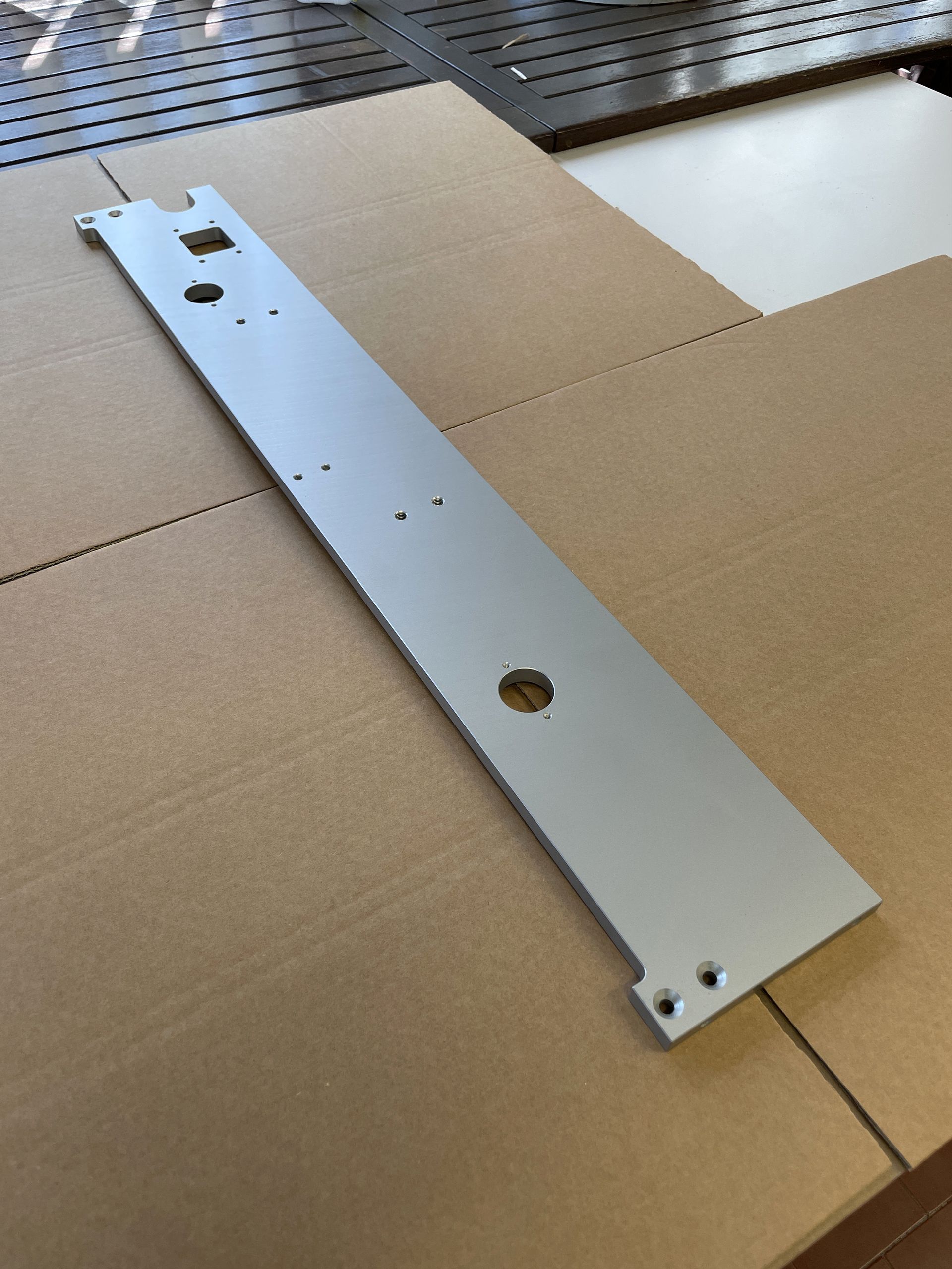

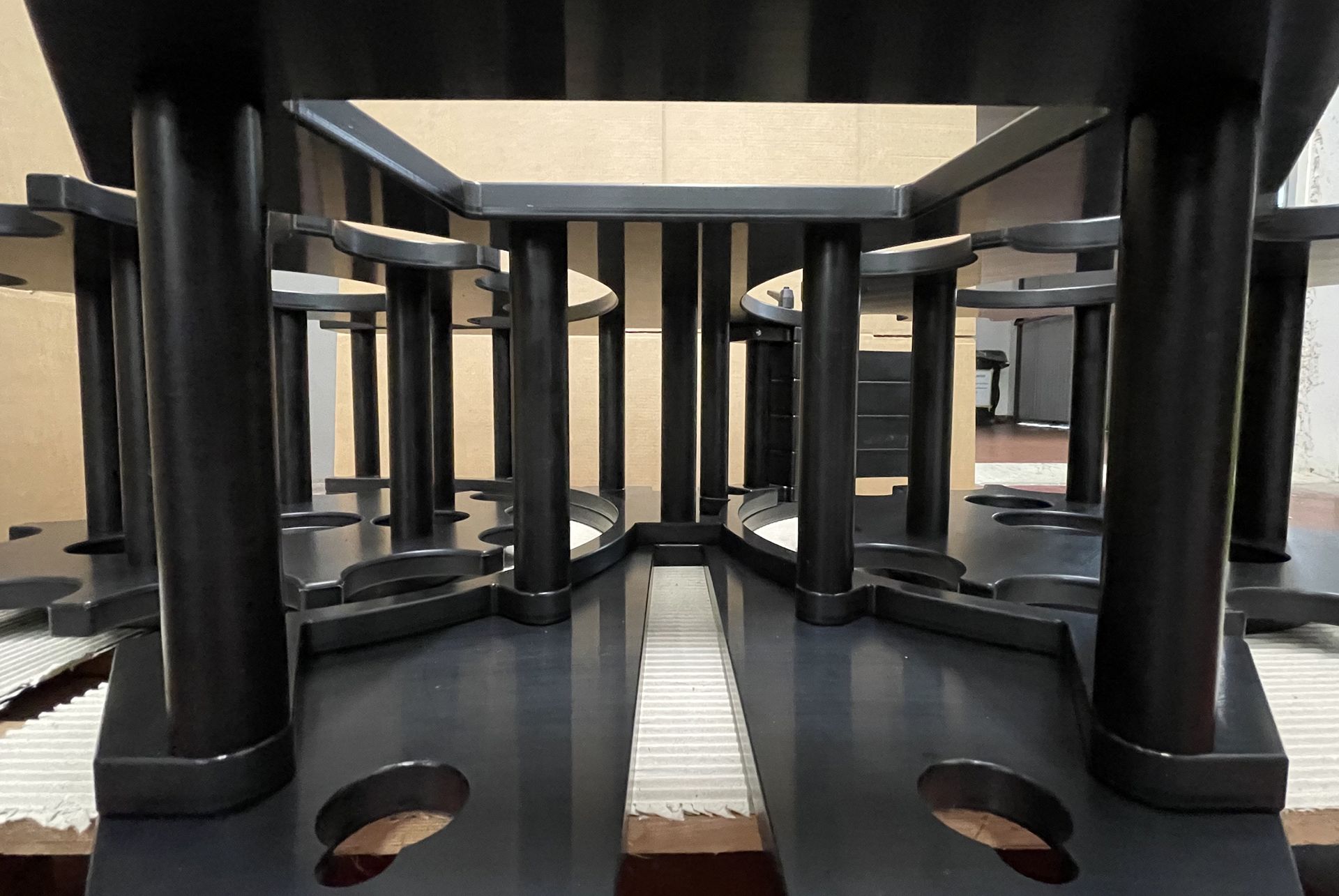

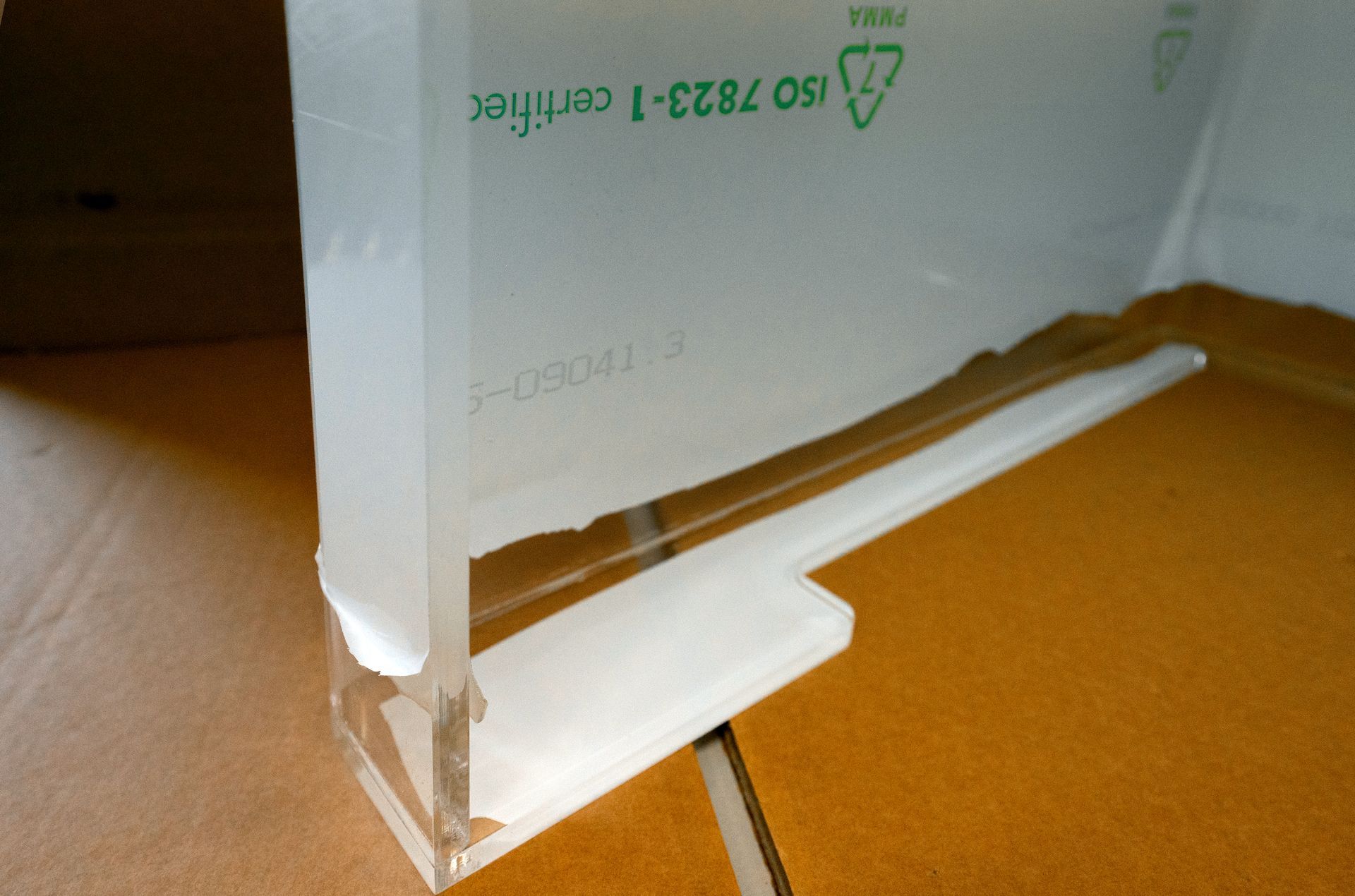

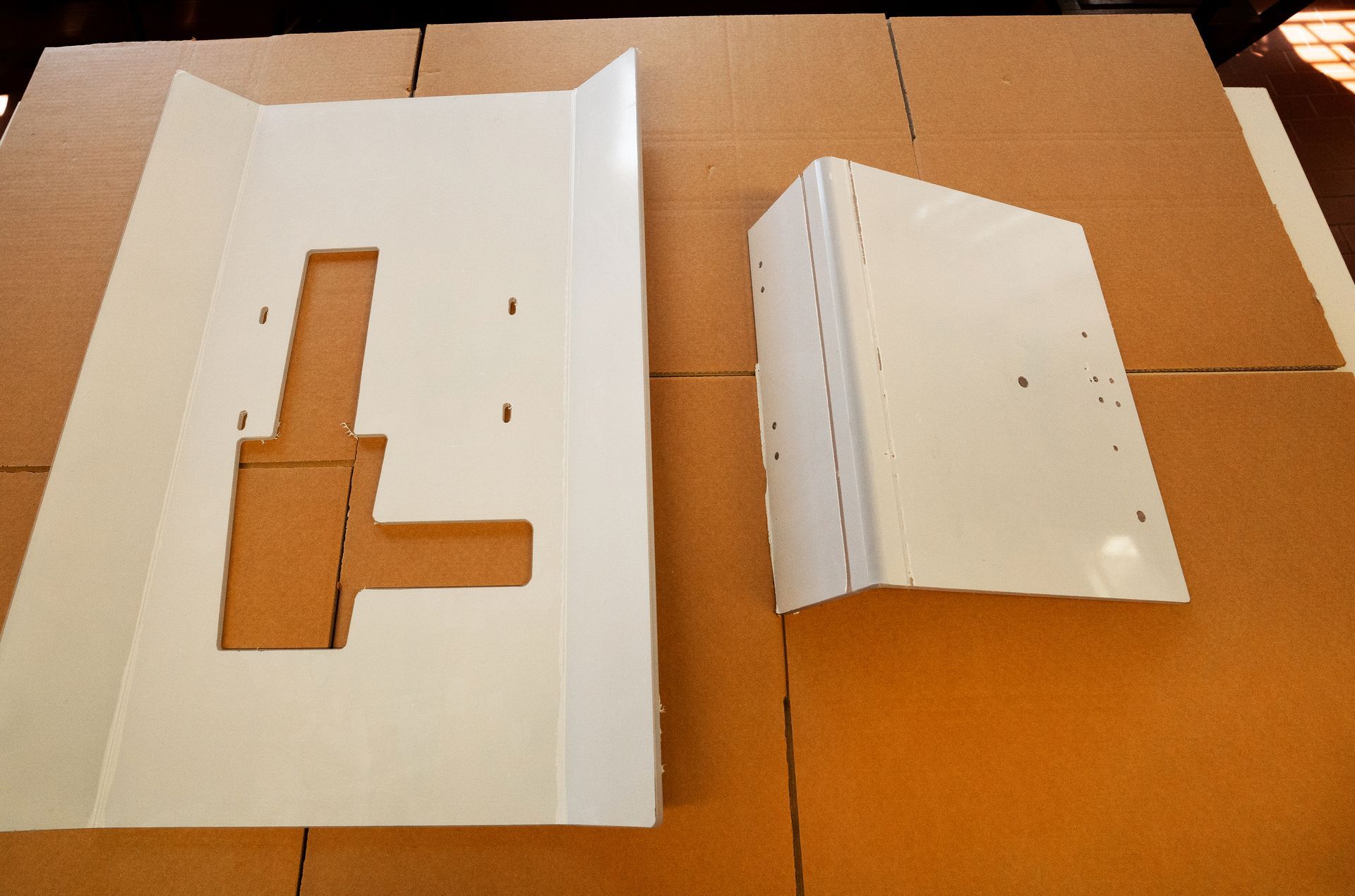

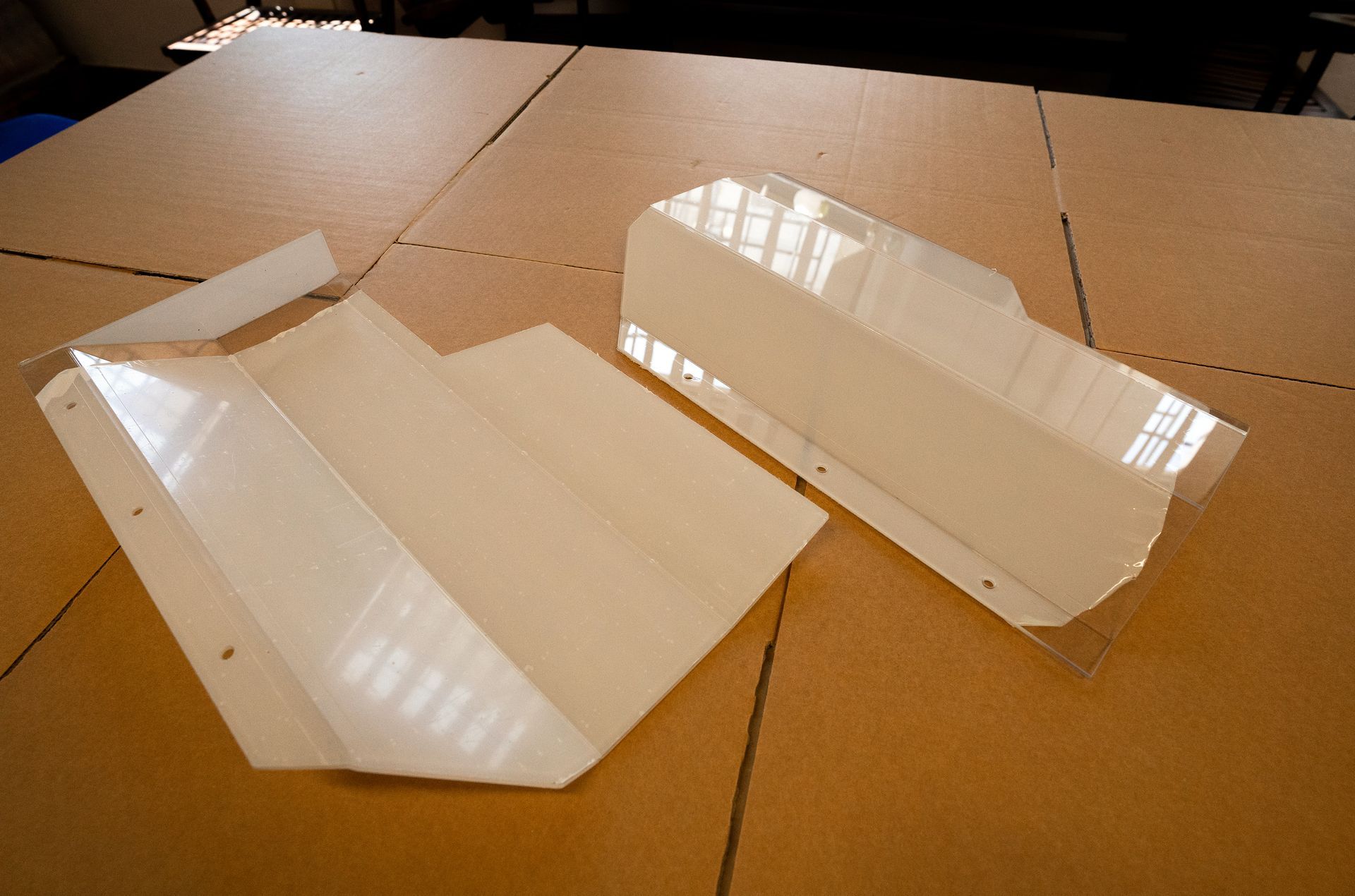

The Bero pantograph department represents excellence in the sector of processing various plastic materials such as HDPE, POM, PET, PTFE, PEEK, PVC etc. and also diversified materials such as aluminum and Dibond. The department uses a series of cutting-edge machines to guarantee precision and high quality workmanship.

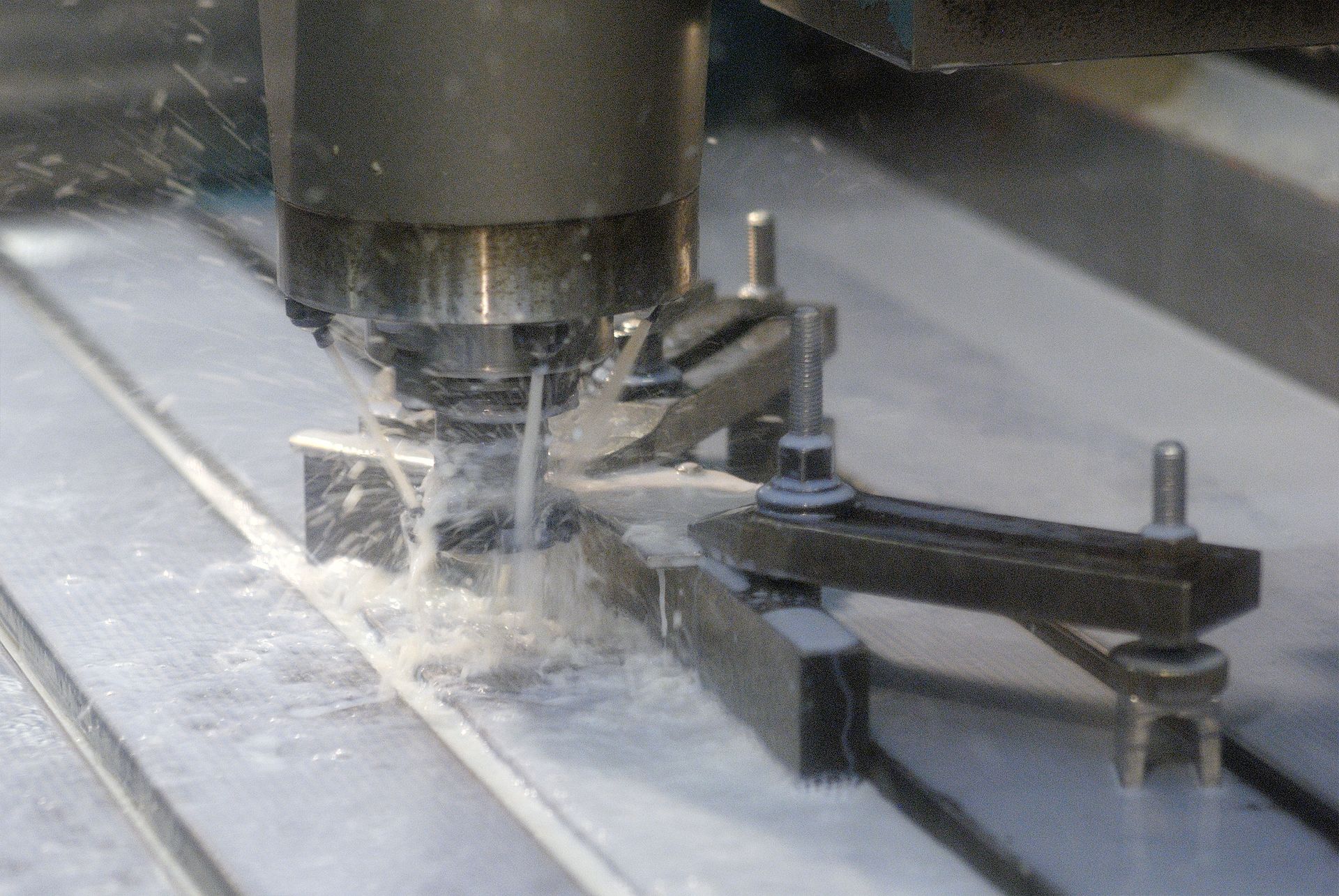

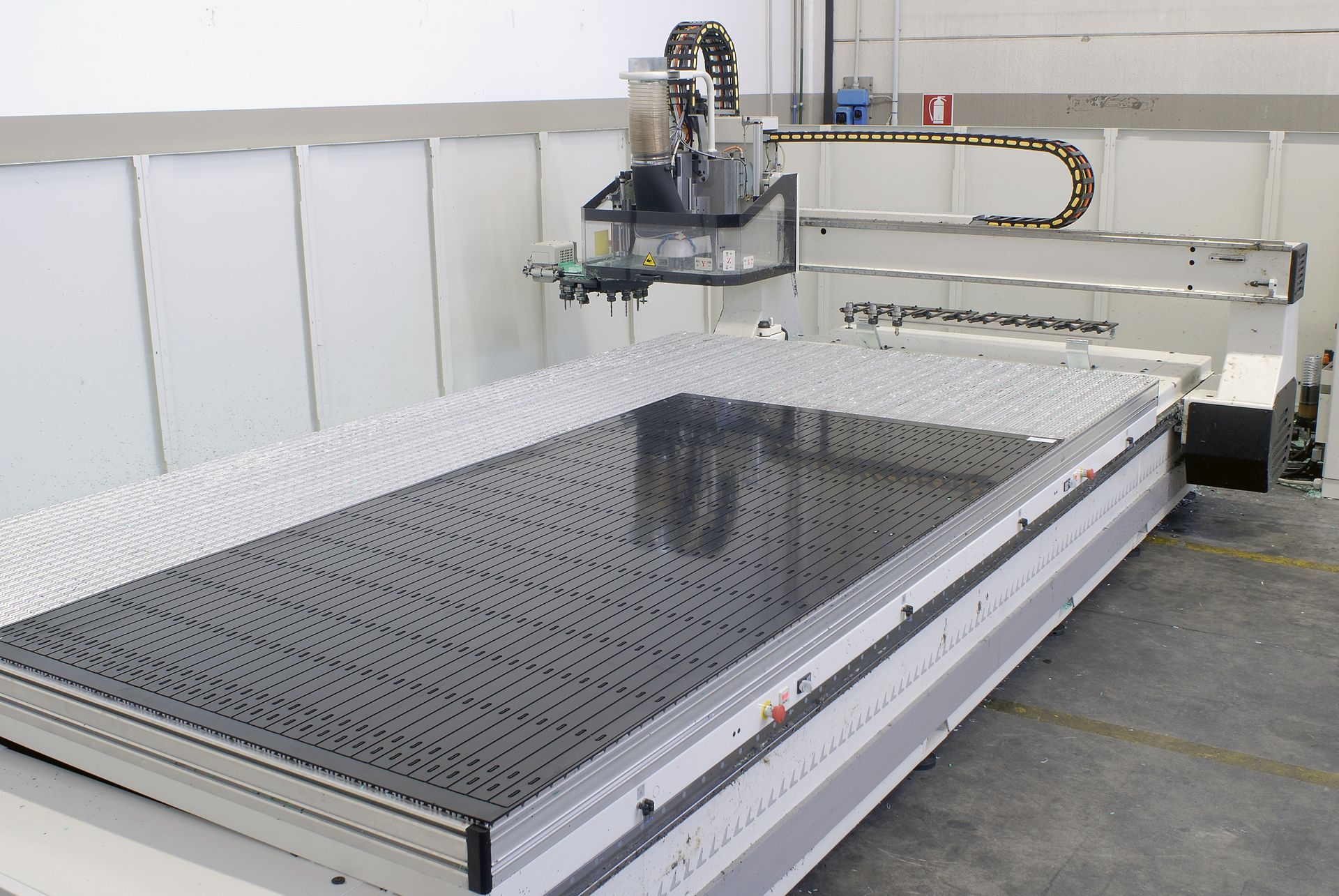

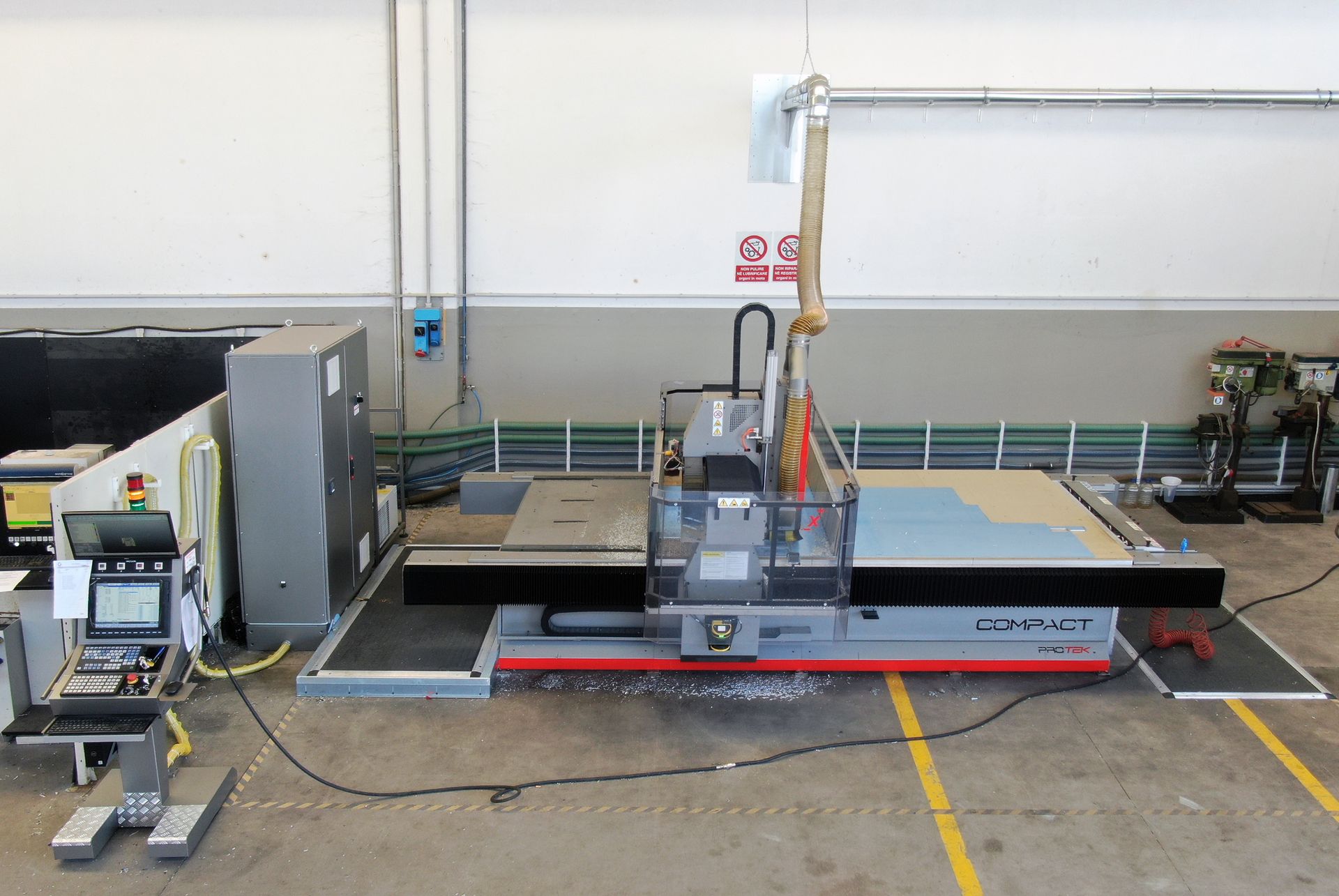

Among these, the PROTEK COMPACT WORKING CENTER with a work surface of 3,110 x 1,620 mm and 3-axis movement, specialized in aluminum and Dibond milling.

ADVANCED TECHNOLOGIES - COMPETENCE - EXPERIENCE

In the processing of plastic materials, the department uses SCM work centers, including the MOD. ACCORD 20 with 3-axis movement and MOD. ACCORD 20 FX, ACCORD FXM and MORBIDELLI MF100 F all with 5-axis movement, thus offering extreme flexibility in processing.

Bero's pantograph department is an example of how advanced technology and professional experience come together to provide innovative and customized solutions, effectively responding to the needs of a constantly evolving market.