PROCESSING OF PLASTIC AND METAL MATERIALS TO YOUR DRAWING

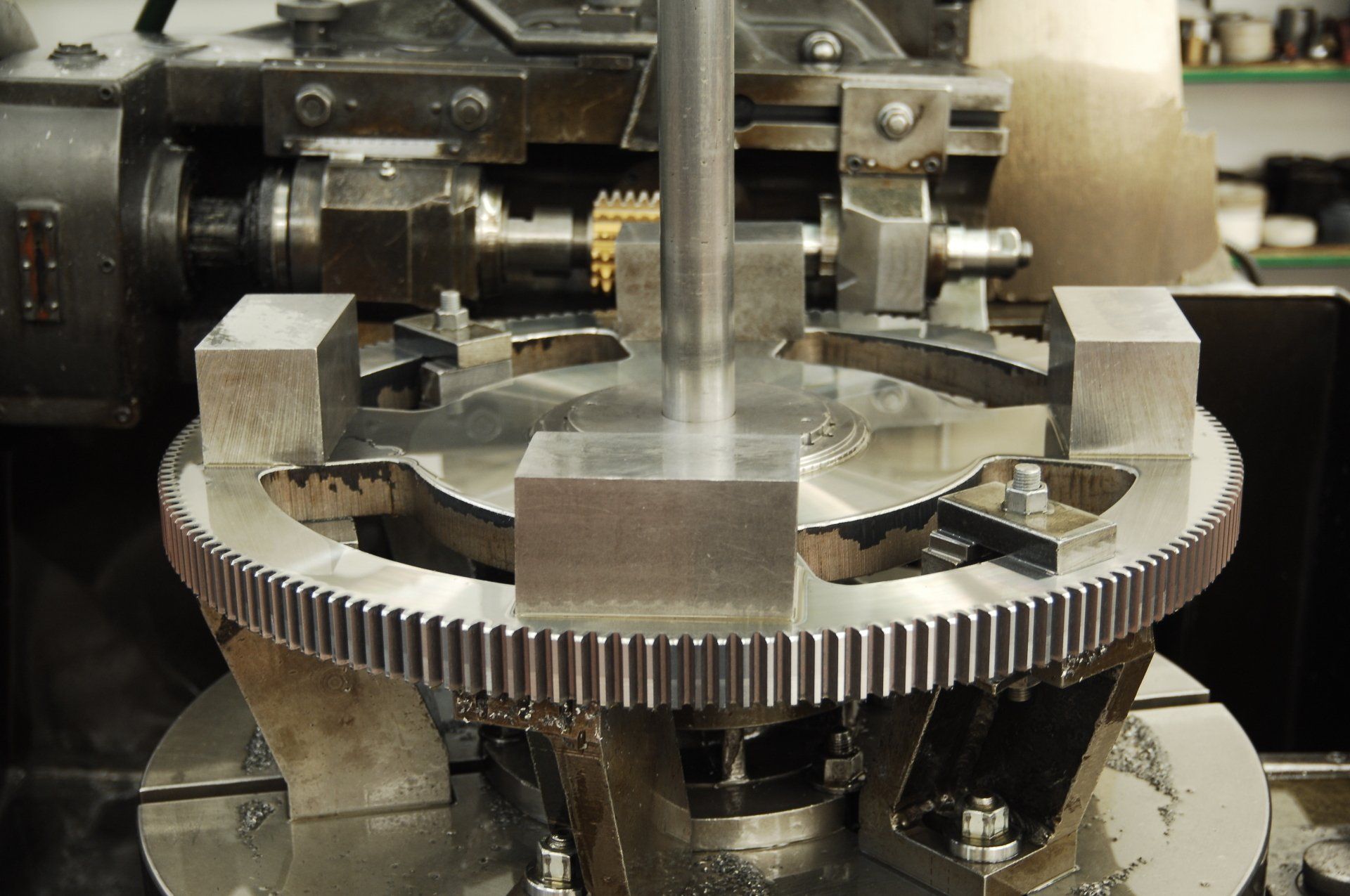

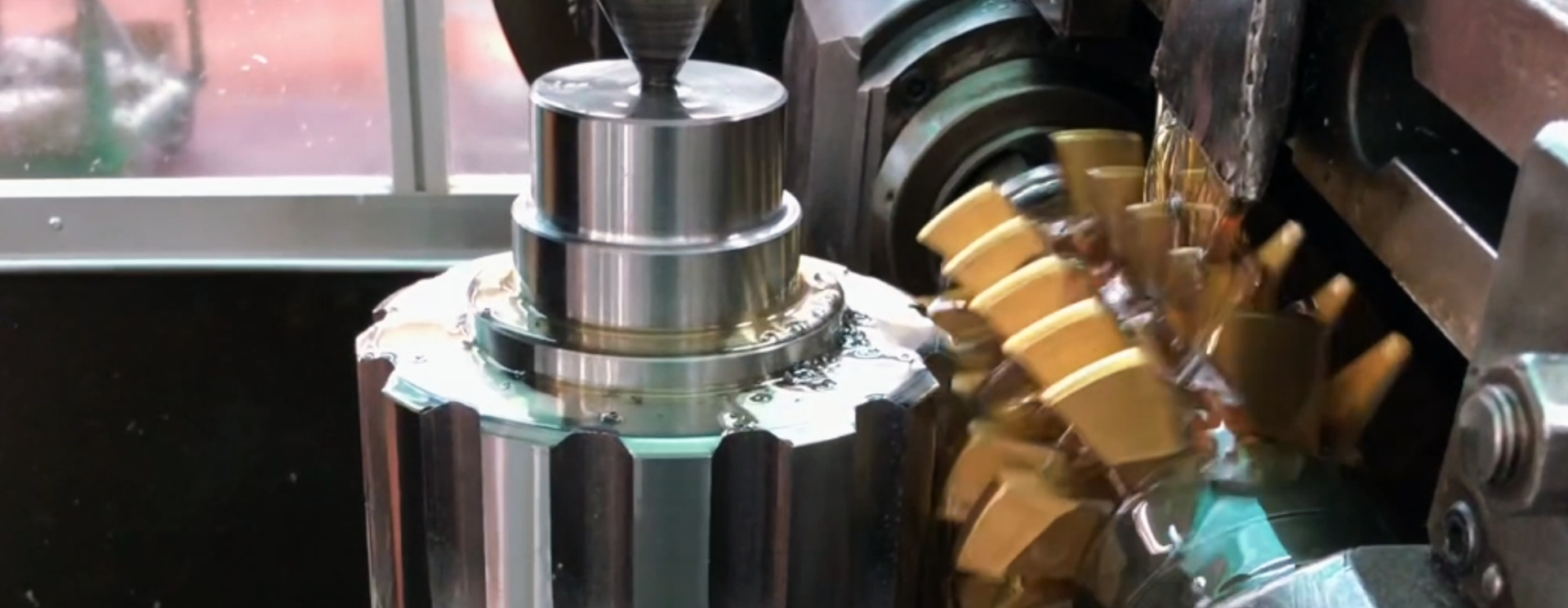

PLASTIC AND STEEL GEARS

BERO SRL

PRODUCTIVE ACTIVITY

Since 2010, BERO SRL, in its factory in Pozzolo di Marmirolo (MN), has specialized in the processing of plastic materials and metals to drawings, and in the production of plastic and steel gears based on customer needs.

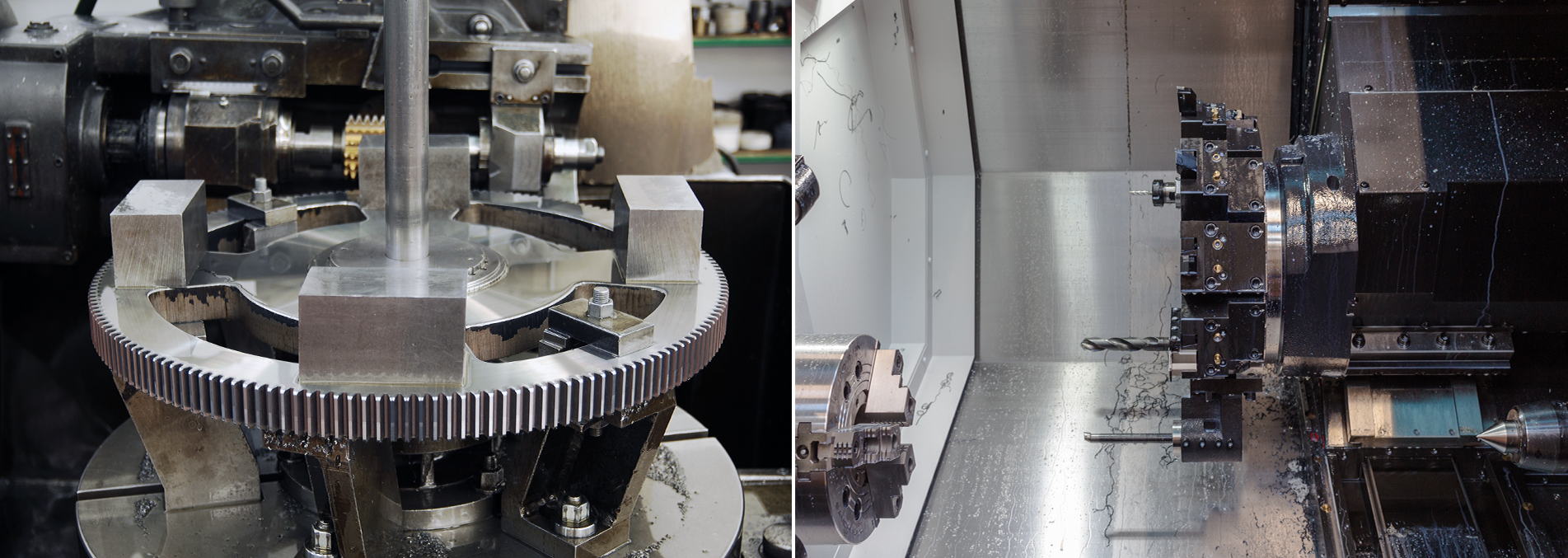

BERO operates in the plant with a production organization made up of 4 departments:

- Hobbing Department

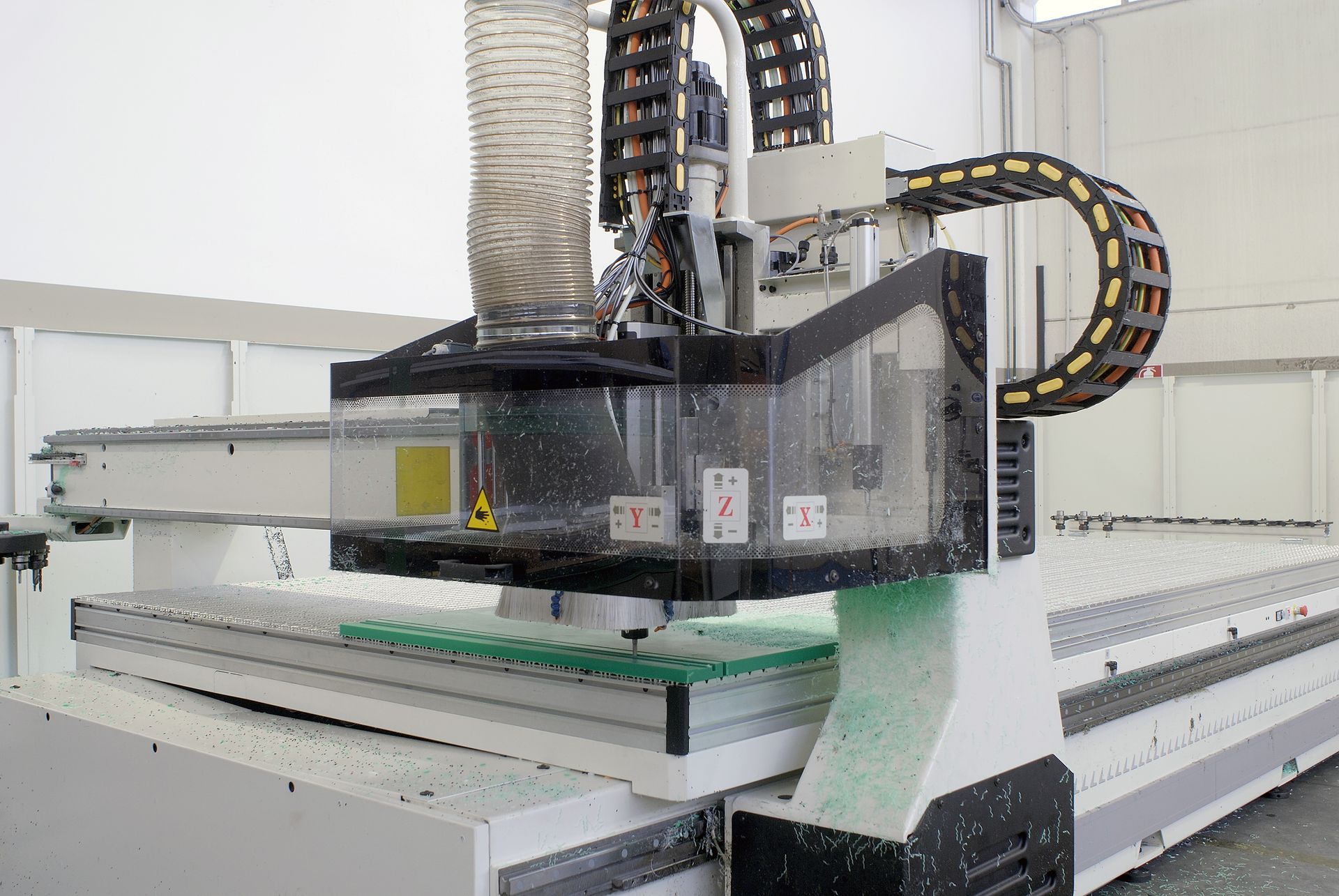

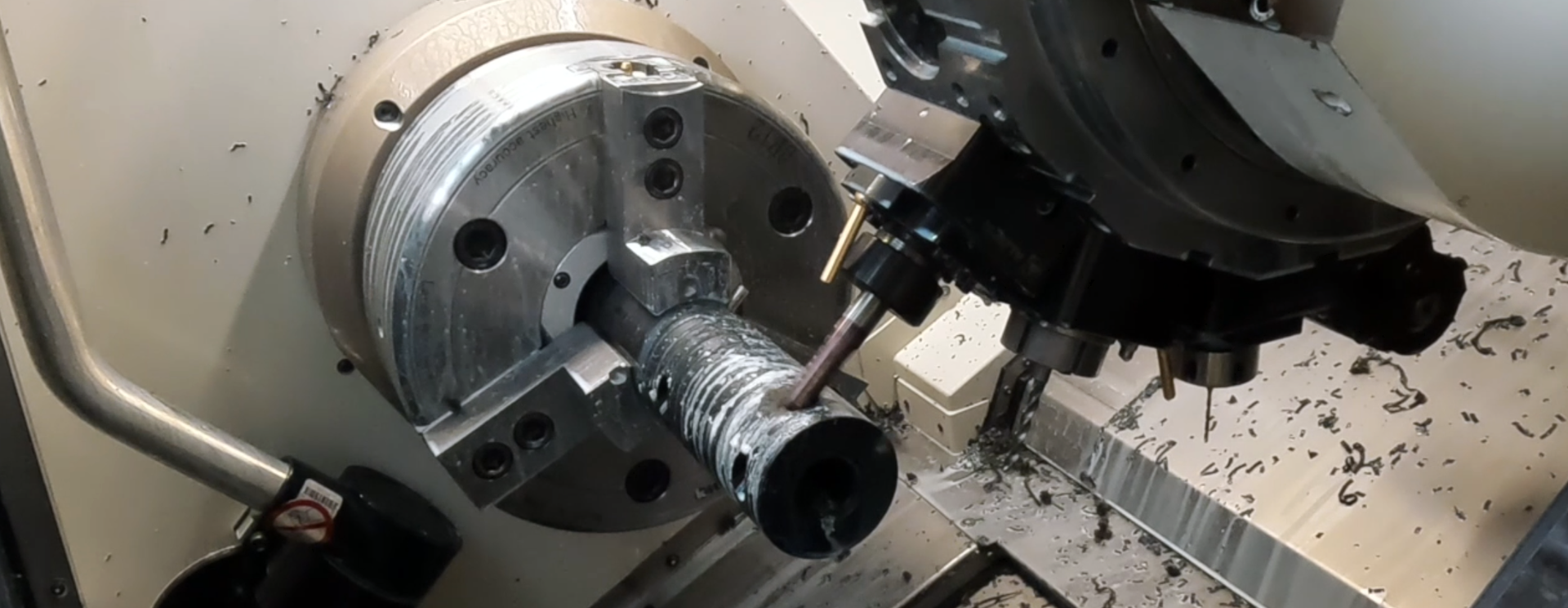

- CNC Milling Department

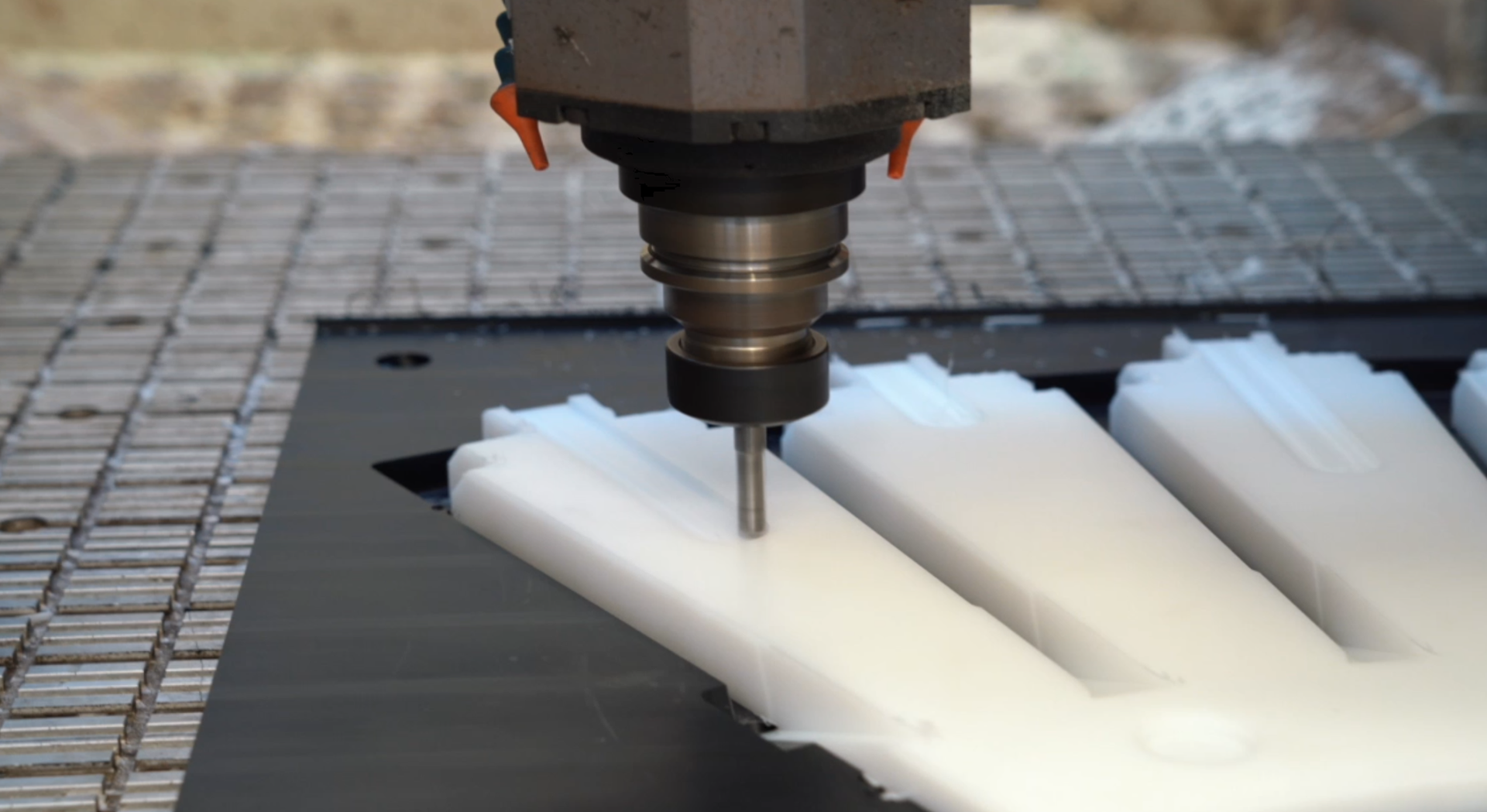

- Pantograph Department

- Turning Department

Within its departments BERO produces plastic and metal components and plastic and metal gears for:

- Food industry.

- Pharmaceutical industry.

- Chemical industry.

- Machines and systems for Personal Care

TYPE OF PRODUCTION

BERO is equipped with a technical office capable of satisfying customer needs, in the factory it produces parts and components in plastic and metal in small, medium and large series, and is also able to develop and produce prototypes based on the technical needs of the customer. customer.

STRONG POINTS - CORPORATE ASSETS

LEADING COMPANY IN STRONG DEVELOPMENT

Strengths outline Bero's profile as a top-level company, capable of standing out in its B2B market not only for the quality of its products, but also for its global approach to production, innovation and customer satisfaction.

- Technological Advancement: Bero has a state-of-the-art machine park, with modern equipment that ensures precision and efficiency in production processes.

- Production Flexibility: The ability to work with a variety of materials, including metals and plastics, and to adapt to different needs, from mass production to customized projects.

- Quality and Reliability: An unwavering commitment to product quality, with rigorous control ensuring compliance with the highest industrial standards.

- Experience and Expertise: A team of experienced and highly qualified professionals, combining knowledge in-depth techniques with long experience in the sector.

- Continuous Innovation: A constant focus on innovation, both in terms of technology and production processes, to always remain one step ahead in the sector.

- Rapid and Punctual Response: An excellent logistics management capability which guarantees the timely delivery of products, fundamental in a B2B context.

- Sustainability and Environmental Responsibility: A production approach that considers the environmental impact, with recycling practices and efficient use of resources.

- Collaboration and Customer Support: A customer-oriented approach, with the willingness to collaborate closely to develop tailor-made solutions that meet specific needs.

- Versatility in Services: The ability to offer a wide range of services, from CNC milling to turning, from gear cutting to pantographs, making Bero a complete and versatile supplier.

- Reputation and Reliability in the Market: A solid reputation built on customer trust and satisfaction, fundamental for long-term partnerships in the B2B sector.