MAIN MACHINE FLEET

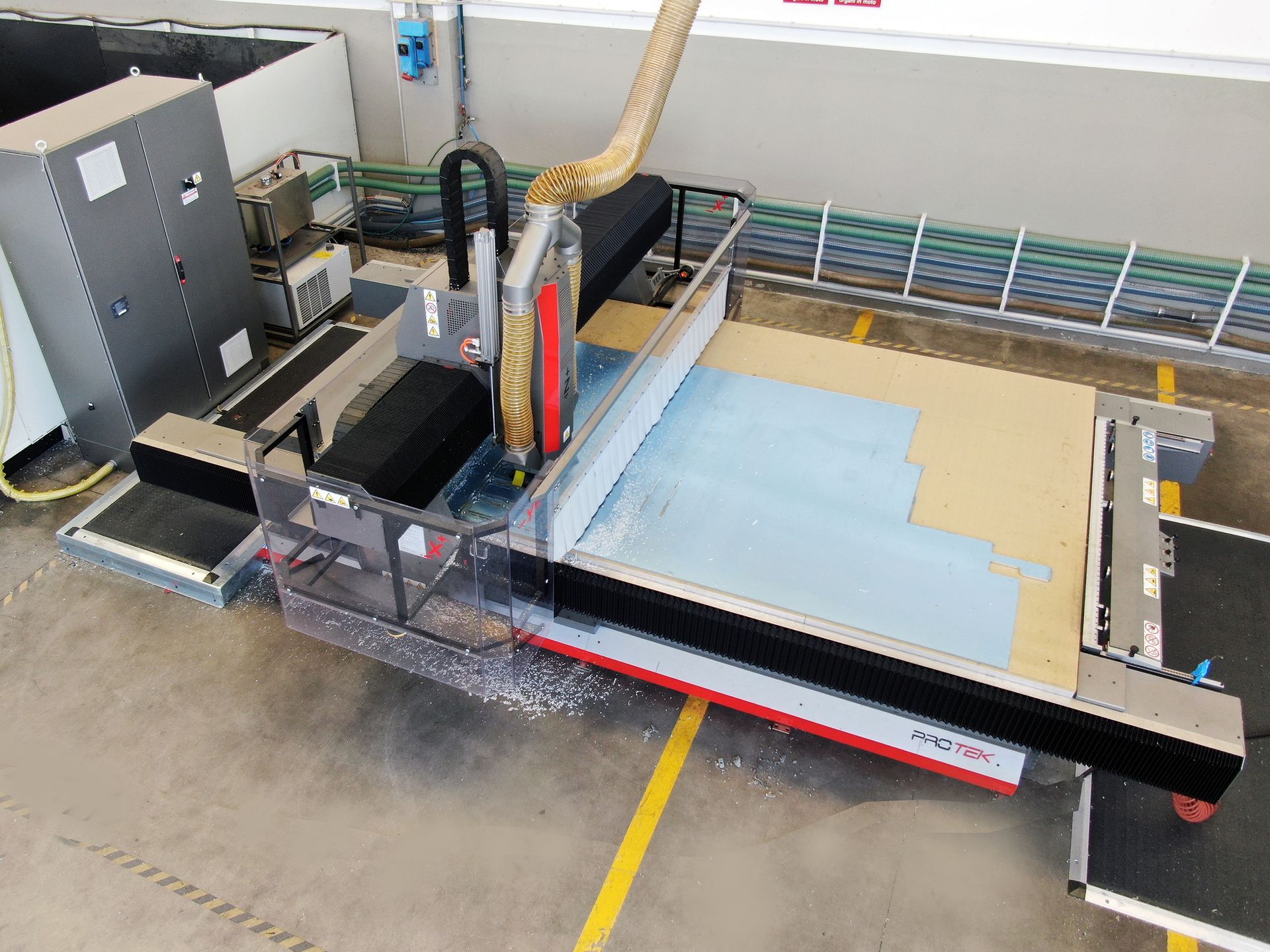

PROTEK COMPACT WORKING CENTER PANTOGRAPH

MAIN MACHINE FLEET

TECHNOLOGY - RELIABILITY - FLEXIBILITY

PANTOGRAPHS FOR MILLING PLASTIC MATERIALS

- NR 1 SCM WORKING CENTER MOD. ACCORD 20 with 4,250 x 2,258 mm work surface and 3-AXLE HANDLING 1 SCM WORKING CENTER MOD. ACCORD 20 FX with 3,160 x 2,258 mm work surface and 5-AXIS HANDLING 1 SCM WORKING CENTER MOD. ACCORD 20 FXM with 3,160 x 2,258 mm work surface and 5-AXIS MOVEMENTNR 1 SCM WORKING CENTER MOD. MF100 F with 3,110 x 1,620 mm work surface and 5-AXLE HANDLING

PANTOGRAPHS FOR ALUMINUM AND DIBOND MILLING

- NR 1 PROTEK COMPACT WORKING CENTER with 3,110 x 1,620 mm work surface and 3-AXIS MOVEMENT

CNC WORKING CENTERS FOR PLASTIC AND STEEL MILLING

- NR 1 HURCO WORKING CENTER mod. VMX64i 40 ATC M5 CNC WinMax® Dual with 1,600 x 900 mm work surface with 3-AXIS MOVEMENT NR 1 OMV WORKING CENTER MOD. BFC 1300 with 1,400 x 500 mm work surface and 4-AXIS MOVEMENT

CNC WORKING CENTERS FOR PLASTIC AND STEEL TURNING

- NR 1 DOOSAN PUMA 2600Y II FA 4-AXIS CNC LATHE NR 1 BIGLIA B750YS 4-AXIS CNC LATHE WITH DOUBLE SPINDLE AND BAR LOADER

TRADITIONAL MACHINE TOOLS FOR TURNING AND MILLING, FINISHING

- NR 5 traditional PARALLEL LATHE UP TO DIAM. 700 MM NR 2 SERRMAC MILLING DRILL NR 10 SERRMAC AND FAMUP COLUMN DRILL

HOBBING MACHINES FOR MANUFACTURING GEARS UP TO DIAM. 1200MM

- NR 1 PFAUTER HOBBING MACHINE NR 3 LORENZ E8 HOBBING MACHINE NR 1 SCN 40/D TYPE HOBBING MACHINE NR 1 CAMS MOD 30 SHUTTERING MACHINE

MACHINE TOOLS FOR ROUND CUTTING

- NR 1 MEP BAND SAW MOD.SHARK 320 NR 1 PEDRAZZOLI BAND SAW NR 2 SICAR RIB

MACHINE TOOLS FOR BENDING POLYCARBONATE AND PLEXIGLASS

- NR 1 HOT BENDER RISCALD 2000 NR 1 HYDRAULIC PRESS OMCN

CONSTANT COMMITMENT TO QUALITY

THE CUSTOMER'S NEEDS AT THE CENTER OF THE COMPANY

Bero stands out in the industrial panorama for its commitment to quality and technological innovation, aspects clearly reflected in its fleet of machines. Each machine, carefully selected, represents a balance between advanced performance and proven reliability.

From traditional parallel lathes, capable of machining large diameter parts, to cutting-edge CNC machining centers such as the HURCO VMX64i and OMV BFC 1300, Bero embodies an approach to manufacturing that values precision and versatility. Additionally, Bero pantographs, including the SCM Accord and Protek Compact models, demonstrate the company's ability to adapt to the specific needs of aluminum, Dibond and plastics processing.

This variety and quality of the fleet is not only a demonstration of technology, but also reflects a company philosophy focused on the creation of complex and tailor-made projects for a demanding and high-level clientele.

Bero, with its mix of traditional and technologically advanced machinery, presents itself as a reliable and competent partner, capable of responding with precision and efficiency to the most complex requests of the B2B market.

The carefully planned organization of the machine park ensures that each phase of production is carried out with the utmost care, guaranteeing results that fully meet customer expectations.

BERO SRL

Address: Strada Boschi, 2/f - 46045

Location: Pozzolo di Marmirolo MN ITALY

Tel: 0376 460126 Fax: 0376 461012

info@bero-srl.it